Alumina Bubble Brick

Alumina Bubble Brick | High-Temperature Lightweight Refractory Brick

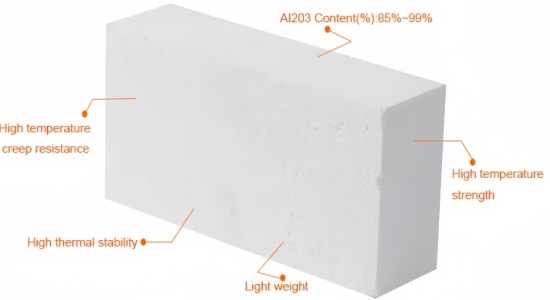

Alumina Bubble Brick is a lightweight refractory insulation material primarily made from high-purity alumina (Al₂O₃). Featuring a unique hollow ball structure and excellent overall performance, it is a high-performance insulating brick ideal for ultra-high-temperature applications (>1500°C) that require lightweight properties and superior thermal shock resistance.

Characters of Alumina Bubble Brick:

✅ 🪶Lightweight & Low Density: Reduces kiln structure load and lowers installation costs.

✅ ❄️High-Efficiency Insulation: Improves energy savings by 30%-50%, minimizing heat loss.

✅ 🔥Ultra-High Temperature Resistance: Ideal for steel, petrochemical, and other extreme high-temperature industries.

✅ ⚡Superior Thermal Shock Resistance: Extends lifespan in kilns with frequent start-stop cycles.

✅ 🧪Excellent Chemical Stability: Resistant to acid, alkali, and reducing atmospheres, making it suitable for metallurgical, chemical, and other complex environments.

Typical Applications of Fireclay Insulating Brick:

✅🏭 High-Temperature Industries: Used for petrochemical cracking furnace linings and insulation layers in ladles/intermediate ladles.

✅🛰️ Specialized Equipment: Applied in thermal insulation for spacecraft high-temperature components and laboratory electric furnace chambers.

✅🍕 Residential Use: Ideal for high-end pizza ovens and regenerative chambers in glass kilns.

Parameters of Alumina Bubble Brick:

Item

LG-85

LG-90

LG-95

LG-99

Al₂O₃ (%)≥

85

90

95

99

SiO₂(%)≤

15

8

0.3

0.2

Fe₂O₃(%)≤

0.2

0.2

0.2

0.15

Bulk Density (g/cm³)

1.4-1.7

1.4-1.7

1.4-1.7

1.4-1.7

Max Service Temperature (℃)

1680

1700

1750

1800

Cold Crushing Strength(MPa)≥

12

10

9

9

Refractoriness Under Load (0.1MPa, 0.6%)℃≥

1650

1700

1700

1700

Reheating Linear Change Rate (1600℃*3h)%

±0.3

±0.3

±0.25

±0.2

Thermal Conductivity (at 800℃ )≤

0.8

1.3

1.5

1.5

FAQ:

Q:What is an alumina bubble brick?

A:Alumina bubble brick is a high-temperature insulating refractory product made from fused alumina hollow spheres. It offers excellent thermal insulation, low thermal conductivity, and can withstand temperatures up to 1800°C.

Q:What’s the maximum operating temperature?

A:Our alumina bubble bricks can withstand continuous temperatures of up to 1800°C (3272°F), depending on the design and service environment.

Q:Are your bricks customizable in shape and size?

A:Yes. We support custom manufacturing based on your technical drawings or application requirements. We also offer various standard sizes for quick delivery.

Q:Do you offer OEM or private labeling services?

A:Absolutely. As a factory, we support OEM, ODM, and private labeling to suit your branding and distribution needs.

Q:Can I get samples before placing a bulk order?

A:Yes, we offer free samples for quality evaluation. You only need to cover the shipping fee.

Q: What is your minimum order quantity (MOQ)?

A:For standard sizes, MOQ is typically 1 pallet (approximately 500–800 bricks). For custom designs, we will confirm MOQ based on your specifications.

Q:How is the product packaged and shipped?

A:Products are packed in fumigation-free wooden crates with protective film. We support FOB, CIF, DDP and deliver globally by sea, air, or rail.

Q:What certifications do you provide?

A:We provide ISO 9001, SGS test reports, and material data sheets to ensure quality and compliance.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd