Refractory Mortar

Refractory Mortar | High-Temperature Fireclay Bonding Mortar

Refractory mortar is a bonding material specifically designed for high-temperature environments, used for laying or repairing refractory bricks and sealing joints in high-temperature equipment. Based on material composition, it can be classified into clay-based, high-alumina, silica-based, and magnesia-based refractory mortar. It consists of refractory powder, binders, and additives. While its strength at room temperature is relatively low, it forms a high-strength ceramic bond at elevated temperatures. The particle size of refractory mortar varies depending on usage requirements, with a typical maximum particle size of less than 1mm, and in some cases, less than 0.5mm or even finer.

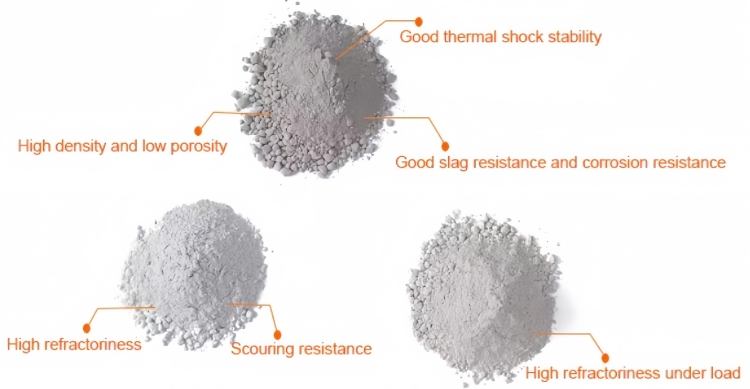

Characters of Refractory Mortar:

• 🛠️Good plasticity and convenient construction;

• 🔗High bonding strength and corrosion resistance;

• 🔥High fire resistance, up to 1650 ℃± 50 ℃;

• 🛡️Good slag resistance and invasiveness;

• 🔄Good thermal peeling property.

Typical Applications of Refractory Mortar:

•🏭 Refractory Brick Joint Bonding in Industrial Furnaces:Used for seamless bonding of firebricks in high-temperature industrial furnaces.•🔥 Kiln and Incinerator Linings:Ideal for constructing durable linings in kilns, rotary furnaces, and waste incinerators.

•🔧 High-Temperature Boiler Repairs:Effective for patching cracks or erosion in boilers exposed to extreme heat and pressure.

Production Process of Refractory Mortar:

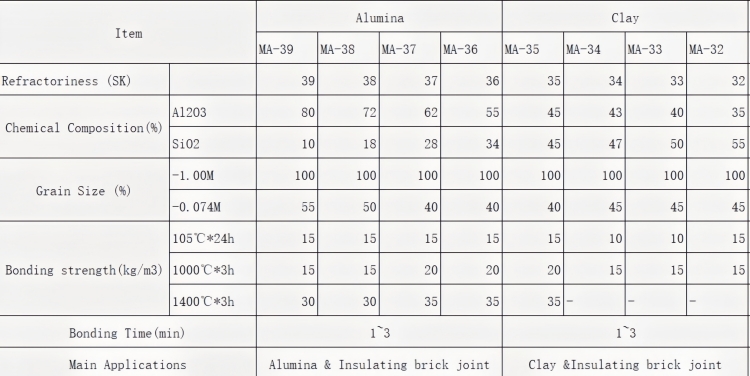

Parameters of Refractory Mortar:

Classification of Refractory Mortars by Main Material Composition:

FAQ:

Type

Main Composition

Refractory Temperature Range

Key Features

Typical Applications

High Alumina Refractory Mortar

Al₂O₃ ≥ 65%

1400–1750°C

Excellent slag resistance, good thermal shock stability

Rotary kilns, steel ladles, electric furnace linings

Fireclay Refractory Mortar

Alumino-silicate fireclay

1400–1750°C

Cost-effective, easy to apply

Chimneys, heating furnaces, domestic fireplaces

Mullite Refractory Mortar

Mullite aggregate

1400–1750°C

Low thermal expansion, long service life

Glass kilns, ceramic kilns

Magnesia Refractory Mortar

MgO ≥ 80%

Above 1700°C

Alkaline resistance, strong slag corrosion resistance

Glass kilns, ceramic kilns

Silicon Carbide Refractory Mortar

SiC ≥ 70%

Above 1700°C

High thermal conductivity, wear-resistant

Roasting furnaces, coke ovens, boiler linings

Q: What is refractory mortar used for?

A: Refractory mortar is a specialized bonding material designed to join firebricks and high-temperature insulating materials. It withstands extreme heat, corrosion, and thermal cycling, making it ideal for use in kilns, furnaces, boilers, fireplaces, and chimneys.

Q:What is the difference between fireclay mortar and high alumina mortar?

A:•Fireclay Mortar: Contains lower Al₂O₃ content (approx. 30–45%), suitable for medium-temperature applications (1300–1400°C).

•High Alumina Mortar: Contains higher Al₂O₃ (≥ 65%), provides superior slag resistance and thermal shock performance, ideal for industrial kilns operating at 1400–1750°C.

Q: How do I choose the right type of refractory mortar for my application?

A: It depends on several factors:

•Service temperature

•Chemical environment (acidic, basic, neutral)

•Type of structure (furnace, fireplace, rotary kiln, etc.)

•Installation method (manual laying, gunning, self-leveling)

You can consult contact our technical support for tailored recommendations.

Q:What is the shelf life of refractory mortar?

A:ypically 6 to 12 months if stored in a dry, cool, and sealed environment. Moisture or prolonged storage may reduce bonding performance. Please refer to the product’s technical data sheet.

Q:Do you offer OEM/ODM services for fireplace or chimney mortar?

A:Absolutely. We provide customized packaging, branding, and formula adjustments for fireplace and chimney applications. Contact us for OEM collaboration details.

Q:Can refractory mortar be exported internationally?

A:Yes. We export to over 30 countries and offer customizable packaging (25kg bags, 50lb sacks, jumbo bags) that meet international shipping standards.

Q: Do you provide installation guides or videos?

A:Yes, we offer downloadable manuals, video tutorials, and technical support for proper installation, drying, and curing. Please check our [Technical Support] section.

Q: How do I inquire or get a quote for bulk refractory mortar?

A:Please fill out our [RFQ form] or contact us directly via email/WhatsApp. Let us know your required quantity, specifications, and destination port for a prompt quote.

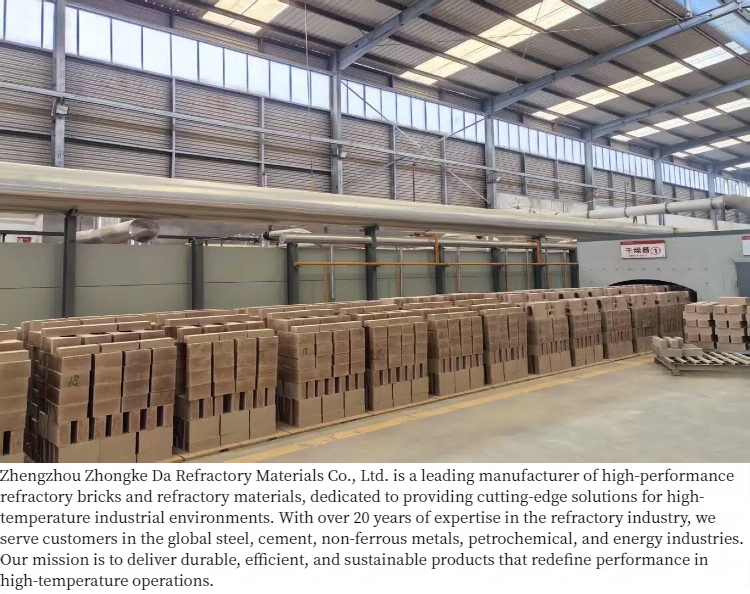

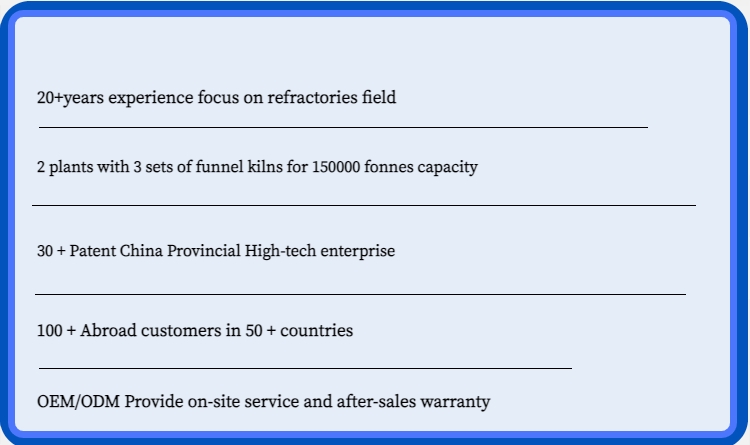

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd