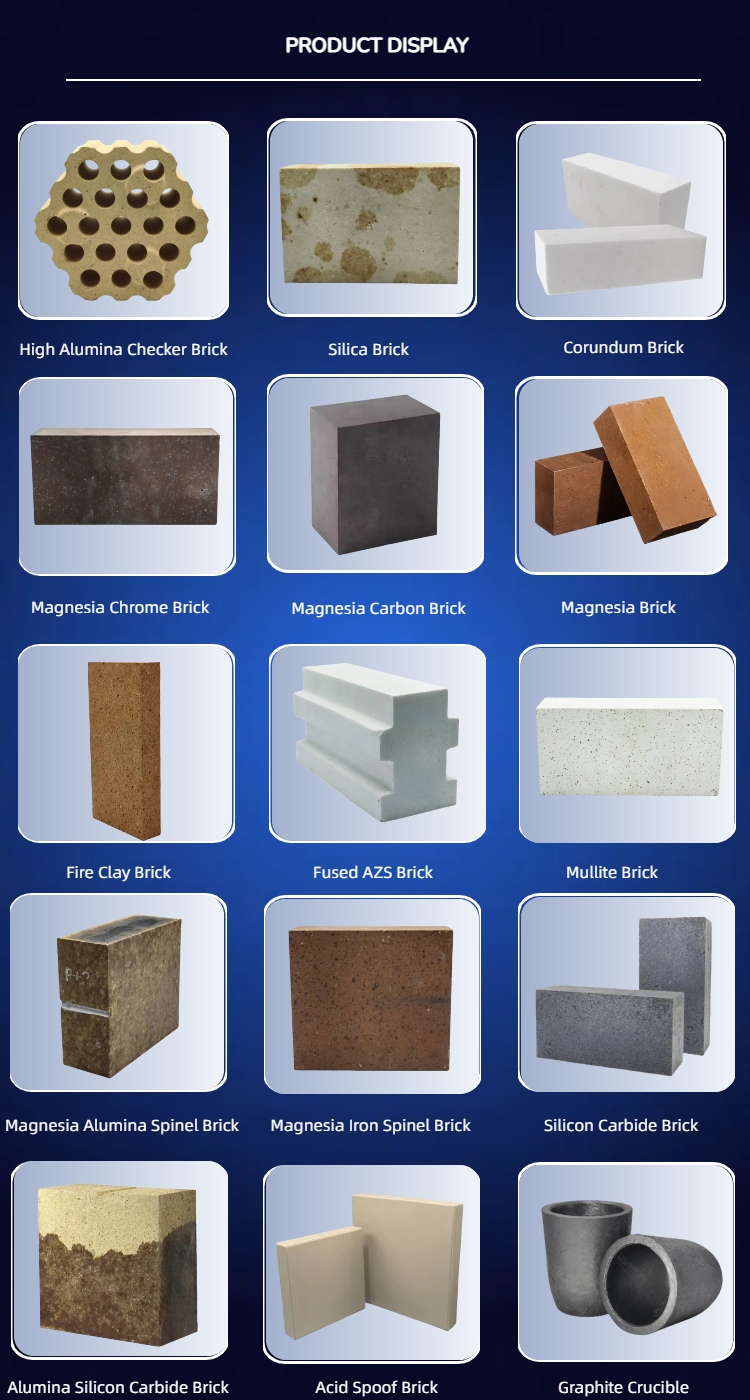

Silicon Carbide Brick

Silicon Carbide Bricks (SiC Bricks)

High strength, excellent thermal conductivity, and superior resistance to abrasion and corrosion.Engineered for extreme industrial conditions.

Silicon Carbide Brick (SiC Brick) is a high-performance refractory material primarily composed of silicon carbide (SiC). Known for its exceptional thermal conductivity, mechanical strength, and resistance to extreme environments, it is widely used in industries requiring durability under high temperatures, abrasion, and chemical corrosion.

Silicon carbide bricks can be divided into oxide bonded (clay bonded, mullite bonded, SiO2 bonded), nitride bonded (Si3N4 bonded, Sialon bonded), self bonded (β-SiC bonded and recrystallized silicon carbide) and silicon infiltration reaction sintered silicon carbide bricks according to the bonding method.

Characters of Silicon Carbide Bricks:

🔥High Thermal Conductivity:Ensures quick heat transfer, reduces energy consumption, and increases furnace efficiency.

🧱Excellent Wear & Erosion Resistance:Withstands abrasive and corrosive conditions, ideal for furnaces, kilns, and linings.

🛡Superior Oxidation Resistance:Maintains structural integrity under oxidative environments at elevated temperatures.

🌍Environmentally Friendly:Long service life reduces maintenance and downtime, minimizing waste.

Applications of Silicon Carbide Bricks:

•🏭Steel and Iron Furnaces | •🔥Waste Incinerator Linings | •🔋Aluminum Electrolytic Cells | •🏺Ceramic Kilns | •⚗️Petrochemical Reactors

• ⛓Non-ferrous Metal Processing Units

Paratemers of Silicon Carbide Bricks:

ltem

Oxide bond SiC brick

Corundum silicon carbide brick

Mullite silicon carbide brick

High alumina SiC brick

SiC, %

≥90

≥70

≥65

≥20

Al₂O₃, %

–

–

≥20

≥55

Fe₂O₃, %

≤0.6

≤1.0

≤1.0

≤1.5

Bulk density, g/cm³

≥2.6

≥2.7

≥2.3

≥2.5

Apparent porosity, %

≤17

≤22

≤20

≤20

Cold crushing strength, MPa

≥100

≥100

≥80

≥80

Refractoriness under load (0.2MPa,0.6%)

≥1650

≥1700

≥1600

≥1600

FAQ:

Q1: What makes silicon carbide bricks better than traditional refractory materials?

A1:•Higher thermal conductivity (3-4x faster than alumina bricks).

•Extreme temperature resistance (up to 1600°C+ in oxidizing atmospheres).

•Superior corrosion resistance to acids, alkalis, and molten metals.

•Longer lifespan, reducing downtime and replacement costs.

Q2: How do I choose the right grade for my application?

A2: •For high thermal shock environments (e.g., kilns): Select nitride-bonded SiC bricks.

•For corrosive chemical exposure (e.g., chemical reactors): Use recrystallized SiC bricks.

•Need a cost-effective option? Clay-bonded SiC bricks balance performance and budget.

Q3: Do you offer custom sizes and shapes?

A3:Yes! We CNC-machine bricks to your specifications (e.g., arches, wedges, special grooves).

Minimum order: 200 bricks for custom orders.

Lead time: +3-5 days vs. standard sizes.

Q4: What certifications do your products have?

A4:Quality: ISO 9001, EN 14001 (EU refractory standards).

Safety: SGS tested for heavy metals & emissions compliance.

Sustainability: Recyclable material (70%+ recovery rate).

Q5: Can I request a sample before bulk orders?

A5:Free samples available for qualified businesses (2-3 brick samples).

Simply Submit a Sample Request with your company details.

Shipping: Samples shipped via DHL/FedEx within 3 working days.

Q6: How do I maintain silicon carbide bricks in high-temperature furnaces?

A6:Avoid rapid temperature changes >200°C/hour.

Use compatible mortars (e.g., our SiC-specific refractory cement).

Q7: What if the bricks get damaged during shipping?

A7:All shipments are insured. Report damage within 48 hours with photos.

We replace damaged bricks free of charge or refund the affected portion.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd