Ceramic Fiber

Ceramic Fiber Products | High-Temperature Industrial Insulation Solutions

Heat resistant up to 1600°C · 40% energy savings · OEM/ODM customization available upon request.

Ceramic fiber products are a type of inorganic, non-metallic, high-temperature resistant material made primarily from alumina (Al₂O₃) and silica (SiO₂). They are produced through high-temperature melting followed by blowing or spinning processes to form fibers. The fibrous structure endows these materials with unique properties, making them widely used in high-temperature insulation, fire protection, and energy-saving applications.

Basic Composition and Production Process of Ceramic Fiber Products

Composition:

• Base Formula: Al₂O₃ (40–60%) + SiO₂ (40–60%), with optional addition of zirconia (ZrO₂) to enhance temperature resistance.

• High-Purity Variant: Al₂O₃ content >72% (e.g., zirconia-containing ceramic fiber), capable of withstanding temperatures above 1600°C.

Production Process:

• Melt-Blown Method: Raw materials are melted at high temperature and then blown into fibers (diameter 3–5μm) using high-speed airflow.

• Spun Fiber Method: Fibers are formed via centrifugal spinning, producing longer and more uniform fibers with higher tensile strength.

• Secondary Processing: The fibers are further processed through needling, layering, or vacuum forming into various shapes such as blankets, modules, and papers.

Types of Ceramic Fiber Products

|

Product Type |

Product Type |

Key Performance Parameters

|

Core Advantages

|

|

Ceramic Fiber Bulk |

Loose fibers, formed by blowing or spinning |

Fiber diameter 3–5μm, service temperature ≤1260°C |

Low cost, ideal for filling complex gaps and composite substrates |

|

Ceramic Fiber Blanket |

Needled felt, available in standard/pure/zirconia grades |

Density 96–128 kg/m³, thermal conductivity 0.12 W/(m·K) |

High tensile strength, main insulation material for industrial kilns |

|

Ceramic Fiber Modules |

Pre-compressed folded blankets + anchor system |

Shrinkage ≤3% (at 1600°C), excellent thermal shock resistance |

Fast installation, reduces heat loss by 30%–50% |

|

Ceramic Fiber Paper |

Wet-formed, ultra-thin flexible sheets |

Thickness 0.5–6 mm, temperature resistance up to 1000°C |

Precision insulation, dust-free, ideal for electronics/battery applications |

|

Ceramic Fiber Cloth/Rope |

Fiber woven with reinforcing metal wire |

Tensile strength ≥200 N/cm², temperature resistance up to 1200°C |

High-temperature sealing, valve wrapping, flexible and easy to install |

|

Ceramic Fiber Shaped Parts |

Vacuum-formed or CNC-cut to specification |

Custom shapes like flanges, cones, cylinders |

Over 99% fit rate, specialized lining for custom equipment |

|

Ceramic Fiber Composite Board |

Fiber + aerogel/calcium silicate composite |

Compressive strength ≥1 MPa, fire rating A1 |

Fire protection for buildings, thermal insulation for new energy battery packs |

Features of Ceramic Fiber Products

Property Technical Parameters

High Temperature Resistance Continuous use temperature: 850–1600°C

Low Thermal Conductivity 0.03–0.12 W/(m·K) (at 600°C)

Lightweight Density: 64–256 kg/m³

Thermal Shock Resistance Withstands rapid heating to 1000°C without cracking

Chemical Stability Resistant to acid and alkali corrosion (except HF and strong alkalis)

Environmental & Safety Compliance Asbestos-free, non-carcinogenic, RoHS/REACH compliant

Applications of Ceramic Fiber Products

•High-Temperature Industries: Lining for metallurgical furnaces, thermal insulation for petrochemical pipelines, sealing for power plant boilers.

•New Energy: Fireproof layers for lithium batteries, thermal insulation for hydrogen storage tanks.

•Transportation: Heat shields for automotive exhaust systems, thermal protection for aerospace vehicles.

•Civil Use: Fire-resistant cores for building fire doors, insulation layers in household ovens.

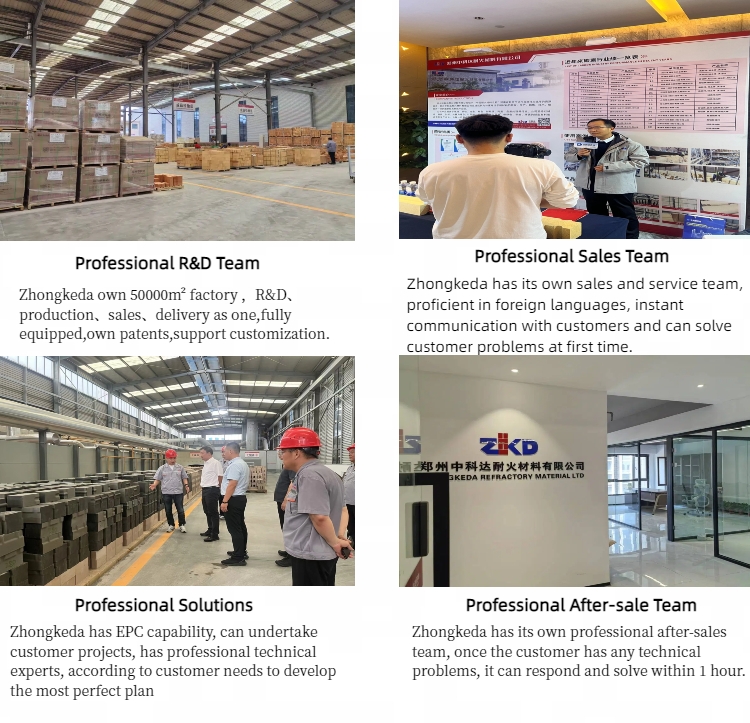

Why Choose Zhongkeda Ceramic Fiber?

•10+ years of refractory manufacturing experience

•Exporting to USA, Russia, Iran, Vietnam, and more

•Strong R&D partnerships (Sinosteel Luoyang, Shanxi Meihai Design Institute)

•OEM/ODM services tailored to your application needs

•Full compliance with international standards (RoHS, REACH, ISO)

Q: What temperatures can ceramic fiber withstand?

A: Standard grades: ≤1260°C continuous use; Zirconia-enhanced grades: up to 1600°C. Download our Temperature Resistance Chart for detailed specs.

Q: How does ceramic fiber improve industrial furnace efficiency?

A: Compared to traditional bricks, ceramic fiber modules:

✅ Reduce heat loss by 40% (verified by thermal imaging)

✅ Cut furnace downtime by 50% due to rapid installation

✅ Extend furnace lifespan 2-3x with superior thermal shock resistance

Q:Do you offer custom sizes and shapes?

A: Absolutely! We provide CNC cutting and vacuum molding services for complex geometries (e.g., flanges, cones). Submit your CAD drawings for a 24-hour quote.

Q: Is ceramic fiber safe for oven insulation?

A: Absolutely! Our FDA-compliant ceramic fiber blankets:

✅ Zero asbestos & carcinogens (SGS Test Report).

✅ Withstand up to 1260°C without releasing harmful fumes.

✅ Reduce outer surface temperature by 50°C+ (Safer to touch!).

Q:How to seal gaps around chimney pipes safely?

A: Use ceramic fiber rope + high-temperature sealant:

• Withstands 1200°C, flexible for irregular gaps.

• No toxic smoke even if charred.

Q: How to make ovens safer and more energy-efficient?

A: Replace traditional glass wool with low-density ceramic fiber blankets (64kg/m³):

• Surface temperature reduced by 70°C (safe to touch).

• Energy consumption lowered by 22% (ErP Directive compliant).

Q: How to install ceramic fiber in existing furnaces?

A: 3 proven methods:

Anchor-based modules – No furnace downtime.

Spray coating – For irregular surfaces.

Layered blankets – Budget-friendly retrofit.

Q: Do you provide installation guidance?

A: We offer:

• Video tutorials for DIY projects

• On-site engineer support for large orders

• Lifetime technical consultation

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd