Mullite Insulation Brick

Mullite Insulating Brick | Lightweight Refractory Brick for High-Temperature Furnaces

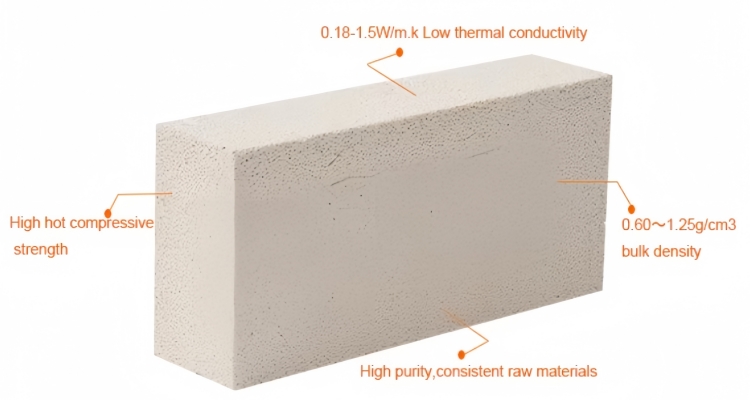

Product Overview:Mullite insulation brick is a lightweight refractory material primarily composed of mullite (chemical formula Al₆Si₂O₁₃), specifically designed for high-temperature insulation. It features a porous structure, low density, lightweight properties, and excellent thermal insulation performance. As a key material in high-temperature industries that emphasizes "lightweight heating," mullite insulation brick achieves efficient insulation through its porous structure. Although its strength is limited, its stability under extreme temperatures is irreplaceable.

Character of Mullite Insulating Brick:

🔥 High-Temperature Resistance: Can withstand long-term use at 1350–1600°C and endure even higher temperatures for short periods.

🛡️Excellent Insulation: Low thermal conductivity (0.2–0.5 W/m·K) effectively blocks heat transfer.

⚡Thermal Shock Resistance: Low thermal expansion coefficient allows it to withstand rapid temperature fluctuations without cracking.

🧪Corrosion Resistance: High stability in acidic and alkaline environments, making it suitable for industrial furnaces and other demanding applications.

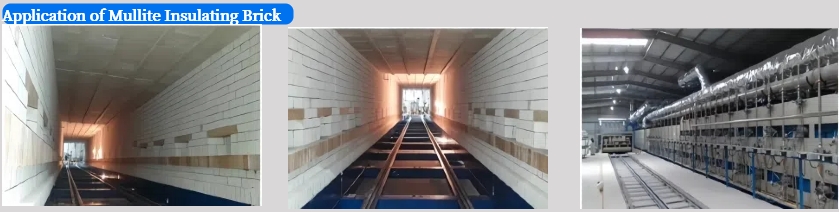

Typical Applications of Mullite Insulating Brick:

⚒️ Metallurgical Industry: Used as an insulating lining for ladles, heating furnaces, and annealing furnaces.

🔥 Glass & Ceramic Kilns: Serves as the insulation layer in melting kilns and kiln cars, reducing heat loss.

⚗️ Petrochemical Equipment: Provides high-temperature protection for cracking furnaces and reforming furnaces.

🌿 Environmental Protection: Used in waste incinerators and boilers for thermal insulation.

Parameters of Mullite Insulation Brick

FAQ:

Item

JM23

JM26

JM28

JM30

AL₂O₃(%)

38-44

50-58

65-70

65-70

Fe₂O₃(%)

1

0.9

0.8

0.7

Classification Temperature(℃)

1350

1430

1540

1600

Bulk Density(g/cm³)

0.6-1

0.8-1

0.8-1

0.8-1

Reheating Linear Change(%)CT-30℃*8h

1250℃ -0.5

1400℃ -0.5

1500℃ -0.5

1550℃ -0.5

Cold Crushing Strength(Mpa)

3.0-4.5

3.0-4.5

3.0-4.5

3.0-4.5

Modulus of Rupture(Mpa)

1.5

1.7

1.8

2.0

Thermal conductivity400℃(W/m.k)

0.25

0.27

0.32

0.41

Thermal Expansion1000℃(%)

0.5

0.7

0.8

0.9

Q: What temperatures can your mullite bricks withstand?

A: Our bricks can withstand continuous working temperatures from 1260°C to 1450°C, depending on the grade. Special grades are available for higher thermal requirements.

Q: Are your mullite bricks available in different grades and densities?

A: Yes. We manufacture a variety of grades with different densities (0.6–1.2 g/cm³), thermal conductivity, and alumina content. Custom solutions can be provided based on your project needs.

Q: Can you customize brick sizes for our project?

A: Absolutely. In addition to standard sizes like 230×114×65mm, we offer full customization in shape, size, and even brick design (e.g., tongue-and-groove, arch bricks).

Q: What is your minimum order quantity (MOQ) for bulk orders?

A: For wholesale orders, our MOQ typically starts from 1 pallet (≈ 500–1000 bricks depending on size). However, we’re flexible for trial orders and long-term partnerships.

Q: How do you package and ship mullite bricks?

A: We use fumigated wooden pallets with plastic film wrapping and corner protection to ensure safe delivery. Shipping can be arranged by sea, air, or land according to your needs.

Q: Do you offer OEM or branding services?

A: Yes, we support OEM/ODM production with your brand, markings, and packaging requirements. We also provide neutral packaging for distributors.

Q: Can I get free samples for testing?

A; Yes. Free samples are available for material testing and compatibility evaluation. Please contact us with your specs to request a sample.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd