Ceramic Fiber Module

Ceramic Fiber Modules | High-Temperature Insulation Materials | Wholesale Refractory Modules for Industrial Furnaces

Professional supply of ceramic fiber modules, suitable for industrial high-temperature furnaces, heat treatment equipment, steel & cement kilns, and other applications. Lightweight and highly efficient, easy to install. Custom solutions available with bulk order discounts. Explore the ideal ceramic fiber insulation solution for your project.

Ceramic fiber modules are made by folding and laminating ceramic fiber needled blankets, which are then pre-compressed into modular units and paired with metal anchors (such as alloy steel pins and clips). Once installed, the modular design expands to form a seamless lining, offering both thermal insulation and structural stability. Ceramic fiber modules are an ideal choice for upgrading high-temperature industrial kilns, especially in scenarios requiring rapid installation, high-efficiency insulation, and long service life.

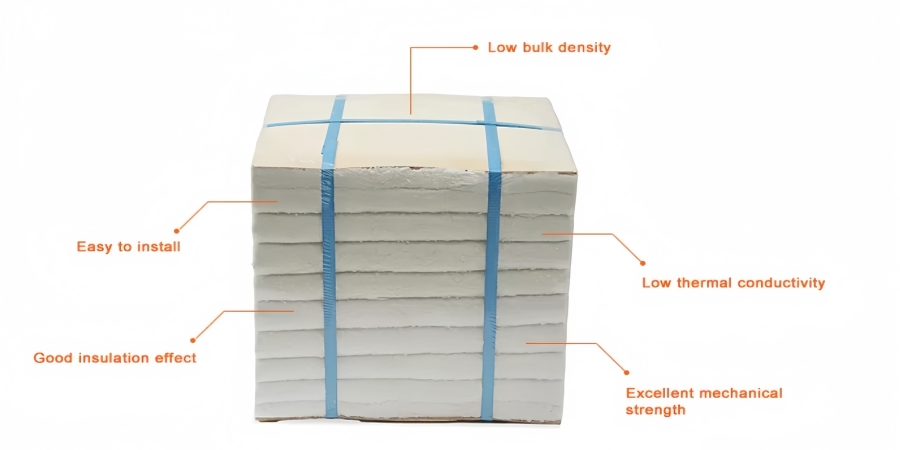

Feature of Ceramic Fiber Modules:

🔧Fast Installation: Pre-compressed modules with anchors – cut downtime by 50% vs. traditional bricks.

🔥Extreme Heat Resistance: Withstands 1430°C (zirconia grade), perfect for furnaces & kilns.

💡Energy Savings: Low thermal conductivity (0.12 W/m·K) reduces fuel costs by 20-40%.

⚖️Durable & Lightweight: 5-8 year lifespan, density 200kg/m³ (1/5 weight of refractory bricks).

🌱Eco-Friendly: Asbestos-free, low bio-soluble fibers (EU REACH compliant).

Application of Ceramic Fiber Module

🏺Ceramic industry: tunnel kiln, shuttle kiln, roller kiln.

🛢️Petrochemical industry: atmospheric pressure furnace, converter, coking furnace, cracking furnace, heating furnace, flue, etc.

🏗️Steel industry: ladle cover, heating furnace, annealing furnace, hood furnace, stepping furnace, hot air pipes and pipes, etc.

🌳Environmental protection and energy saving industry: waste incinerator, RTO waste gas treatment furnace, SCR environmental protection catalytic furnace, etc.

Technical Specifications of Ceramic Fiber Modules

Item

ZK1050-COM

ZK1260-ST

ZK1260-HP

ZK1350-HA

ZK1430-Zr

ZK1600-PMF

Classification Temperature(℃)

1050

1260

1260

1350

1430

1600

Liner Shrinkage, % (24h, 200kg/m³)

≤3.0

950°C

≤3.0

1000°C

≤3.0

1050°C

≤3.0

1200°C

≤3.0

1300°C

≤1.5

1450°C

Thermal

Conductivity

Rate, W/(m·k) (128kg/m³)

600℃

0.2

0.16

0.16

0.16

0.15

/

800℃

0.25

0.23

0.23

0.23

0.23

0.27

1000℃

/

/

0.36

0.36

0.35

0.38

Al2O3,(%)≥

38

42

45

52

37

72

Al2O3+SiO2, (%)≥

97

97

98

98

83

99

ZrO₂(%)

/

/

/

/

15-17

/

Other(%)≤

1.0

1.0

1.0

1.0

1.0

1.0

Types of Ceramic Fiber Modules:

By Temperature Rating

🔥1050℃ Standard Ceramic Fiber Module:Ideal for general industrial kilns and furnaces. This cost-effective solution provides excellent insulation performance for equipment operating below 1050℃. Commonly used in annealing furnaces, heat treatment furnaces, and medium-temperature kilns.

🔥 1260℃ High Purity Ceramic Fiber Module:Made from high-purity raw materials, offering superior thermal shock resistance and corrosion resistance. Designed for environments up to 1260℃. Widely used in steel, power generation, and ceramic industries.

🔥 1350℃ High Alumina Ceramic Fiber Module:Formulated with a higher Al₂O₃ content, this module offers enhanced thermal performance and durability. Suitable for high-temperature kilns, tunnel kilns, roller hearth furnaces, and metallurgy applications.

🔥 1430℃ Zirconium Ceramic Fiber Module:Reinforced with ZrO₂ for maximum temperature resistance and structural stability. Ideal for extreme high-temperature environments such as petrochemical heaters, glass furnaces, and aerospace thermal systems.

FAQ:

Q: What are the advantages of ceramic fiber modules compared to refractory bricks?

A: Ceramic fiber modules are lighter, offer better thermal insulation, and are quicker to install. They are ideal for furnace structures that require energy efficiency and fast maintenance.

Q: Do you provide installation guidance?

A: Yes, we provide detailed installation drawings, instructional videos, and technical support to ensure smooth on-site installation.

Q: Can you customize non-standard or irregular-shaped modules?

A: Absolutely. We offer custom fabrication for non-standard sizes and special-shaped ceramic fiber modules based on your project requirements.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd