High Alumina Insulation Brick

Lightweight High Alumina Insulating Brick

High Strength • Excellent Thermal Insulation • Custom Sizes Available

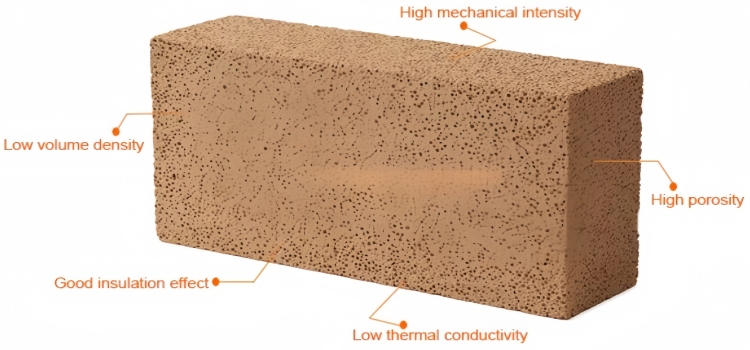

Characters of High-alumina Insulating Brick :

•🔥High-Temperature Resistance: Al₂O₃ ≥48%, withstands 1600°C long-term, 1700°C short-term; excellent oxidation resistance.

•🪶Lightweight & Energy-Efficient: 50-70% porosity, 0.8g/cm³ density; reduces heat loss by 20%+ and fuel costs.

•🧪Acid Resistance: Optimized formula resists acidic slag; 3x lifespan vs. standard clay bricks.

•⚡Thermal Shock Resistance: Low expansion (4.5×10⁻⁶/°C); endures 1000+ rapid cooling/heating cycles.

•📏Customization: ±1mm precision cutting, density/size tailoring for complex kiln structures.

Application Scenarios of High-alumina Insulating Brick:

✅🏭 Metallurgical Industry: Used in ladle covers, heating furnace roofs, and annealing furnace linings.

✅⚗️ Petrochemical Equipment: Ideal for radiation sections of cracking furnaces and insulation layers of reforming furnaces.

✅🌱 Power & Environmental Protection: Applied in circulating fluidized bed boilers and waste incinerators.

✅🔬 High-Temperature Experimentation: Suitable for muffle furnaces and laboratory high-temperature equipment.

Technical Specifications of High-alumina Insulating Brick:

| Item |

LG-1.2 |

LG-1.0 |

LG-0.8 |

LG-0.7 |

LG-0.6 |

LG-0.5 |

|

Al₂O₃/(%)≥ |

48 |

48 |

48 |

48 |

48 |

48 |

|

Fe₂O₃/(%)≤ |

2.0 |

2.0 |

2.0 |

2.0 |

2.0 |

2.0 |

|

Bulk Density (g/cm³)≤ |

1.2 | 1.0 | 0.8 | 0.7 | 0.6 | 0.5 |

|

Cold Crushing Strength (MPa)≥ |

4.5 | 3.5 | 2.5 | 2.2 | 1.6 | 1.2 |

|

Permanent Linear Change on Heating/(%)(T/℃*12h) |

1400 | 1400 | 1400 | 1350 | 1350 | 1250 |

|

Thermal conductivity W/(m•K)Mean temperature (350±25)℃ ≤ |

0.55 | 0.50 | 0.35 | 0.30 | 0.25 | 0.20 |

FAQ:

Q1: What is the maximum working temperature of your lightweight high alumina insulating bricks?

A1: Our bricks are rated for continuous use up to 1350°C (2462°F), depending on the alumina content. They're ideal for insulating layers in high-temperature industrial furnaces.

Q2: Are these bricks suitable for direct contact with flame?

A2: Lightweight high alumina bricks are primarily used for insulation purposes and should not be exposed to direct flame or heavy mechanical load. For hot face applications, consider dense firebricks or mullite bricks.

Q3: Can you customize the brick size and shape?

A3: Yes, we offer OEM customization based on your drawings or standard dimensions. We can produce arch bricks, special curves, or complex shapes as needed.

Q4: Are the bricks environmentally safe?

A4: Absolutely. Our products are asbestos-free, meet RoHS and REACH standards, and are manufactured in accordance with ISO 9001 quality systems.

Q5: Do you provide free samples for testing?

A5: Yes, free samples are available for qualified B2B buyers. Please contact us with your requirements and shipping details.

Q6: What is the typical lead time for bulk orders?

A6: For standard sizes, our lead time is around 7–15 working days. For custom orders, it may vary depending on the complexity and quantity.

Q7: Do you support international shipping?

A7: Yes, we ship worldwide via sea or air freight. We can also assist with CIF/DDU/DAP terms and work with your freight forwarder if needed.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd