Ceramic Fiber Board

Rigid, Lightweight, Fireproof – Ideal for Furnaces, Kilns, and High-Temperature Equipment

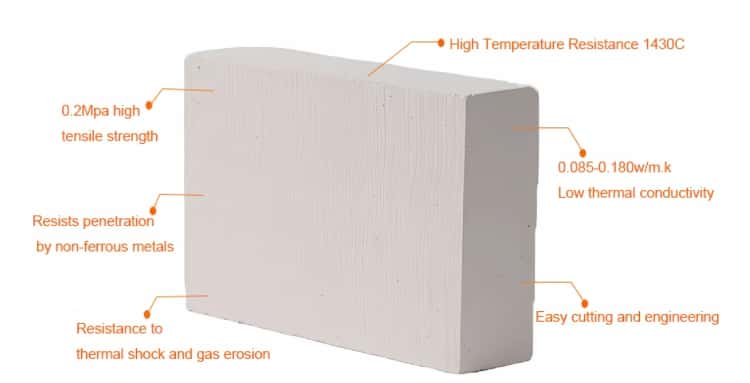

Ceramic fiber board is a high-performance insulation product formed in a vacuum process using ceramic fibers and adhesives. It has a smooth surface with evenly distributed ceramic materials, providing excellent thermal insulation properties. Due to its low thermal conductivity and low heat storage, it does not expand when heated, helping to reduce energy costs and cycle times while protecting refractory surfaces from thermal shock and chemical erosion. With its combination of insulation, mechanical strength, and dimensional stability, ceramic fiber board is an ideal choice for rigid insulation applications in high-temperature industries.

🔥Extreme Heat Resistance: Withstands up to 1430°C (zirconia-enhanced grade).

🏋️High Strength: Compressive strength 1-5 MPa, ideal for load-bearing insulation.

❄️Superior Insulation: Thermal conductivity 0.08-0.15 W/m·K (800°C), reducing energy costs by 20-30%.

🛡️Rigid & Durable: Resists airflow erosion and mechanical impact (vs. fiber blankets).

🪶Lightweight: Density 200-400 kg/m³ (1/3 weight of traditional refractory bricks).

🧪Chemical Stability: Resists acid/alkali corrosion (except HF).

🌱Fireproof & Eco-Friendly: Non-combustible (ASTM E136), asbestos-free.

•High-temperature industrial equipment: kiln lining, thermal equipment insulation doors, burner lining plates.

•Specialized and civilian applications: fireproof building materials, household fireplaces and barbecue grills, laboratory high-temperature equipment.

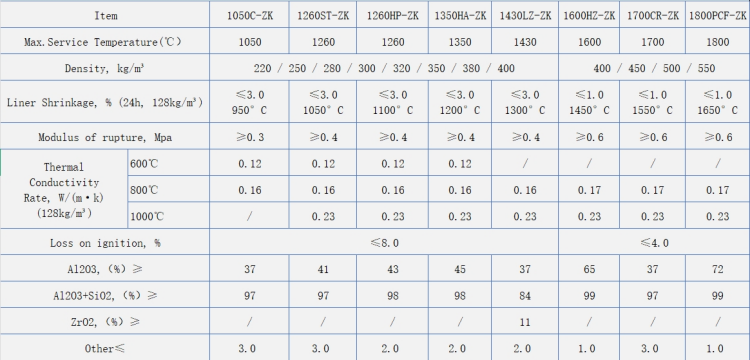

• Ordinary :1100℃

• Standard:1260℃

• High purity type:1360℃

• Containing zirconium type:1430℃

A:Ceramic fiber board is used for high-temperature insulation in industrial furnaces, kilns, fireproof structures, and combustion chambers. It resists direct flame and thermal shock, making it ideal for applications in metallurgy, petrochemical, power generation, and more.

Q:Are you a ceramic fiber board manufacturer or a trader?

A:We are a direct manufacturer of ceramic fiber board, with over 15 years of experience. Our factory in Xinmi City, Henan Province, China produces a full range of insulation boards with various temperature ratings, densities, and thicknesses.

Q:What temperature can your ceramic fiber boards withstand?

A:Our boards are available in several grades:

•1260°C Standard

•1350°C High-Purity

•1430°C Zirconium-Enhanced

All boards are tested for thermal stability and structural integrity under extreme conditions.

Q:Do you offer custom sizes or cutting service?

A:Absolutely. We provide custom cutting services to fit your project requirements. Boards can be trimmed, drilled, or machined to size, and we offer private-label packaging for partners.

Q:Is your ceramic fiber board safe and asbestos-free?

A:Yes. Our boards are 100% asbestos-free, eco-friendly, and comply with RoHS and REACH standards. They are safe for workers, environment, and end-users.

Q:What’s the minimum order quantity (MOQ)?

A:Our MOQ starts at 50 boards or 100m², depending on size and density. Sample orders are available for quality testing.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd