High Alumina Castables

High Alumina Refractory Castable – Durable, High-Temperature Solution for Industrial Furnace Linings

Premium Al₂O₃ Castable for Cement Kilns, Steel Plants, Boilers & More – Excellent Strength, Thermal Shock Resistance & OEM Service Available

High-alumina refractory castable is a type of monolithic refractory material, composed of refractory aggregates, refractory powders, binders, and other additives. It is shapeless, highly flowable, and can be cast or vibrated into shape. It can be used directly or by adding an appropriate amount of water or other liquids. As a new type of refractory material that does not require calcination, it boasts excellent high-temperature resistance, corrosion resistance, and mechanical strength. It is widely used as linings for industrial kilns and high-temperature equipment.

Characters of High Alumina Refractory Castable:

•🔥High-temperature strength: Alumina forms a stable corundum phase (α-Al₂O₃), resulting in a dense structure at high temperatures with excellent compressive and flexural strength.

•🔄Thermal shock resistance: With a low thermal expansion coefficient (approximately 5.0×10⁻⁶/℃), it can withstand frequent rapid heating and cooling cycles, making it suitable for intermittent kilns.

•🛡️Chemical corrosion resistance: It exhibits strong resistance to both acidic slags (such as metallurgical slag) and alkaline environments (such as cement kilns).

•🛠️Easy application: It can be cast, vibrated, or sprayed, making it ideal for complex kiln linings. It does not require sintering and can be used directly.

Typical Applications of High-alumina Refractory Castable:

•🔥Metallurgical Industry: Blast furnace iron troughs, hot blast stove domes, ladle linings, and electric furnace roofs.

•🏗️Building Materials Industry: Front kiln mouth of cement rotary kilns, grate coolers, and regenerator chambers of glass melting furnaces.

•⚗️Petrochemical Industry: Lining of cracking furnaces, combustion chambers of gasifiers, and doors of coking furnaces.

•⚡Power Industry: Cyclone separators and burner linings in circulating fluidized bed (CFB) boilers.

Production Process of High-alumina Refractory Castable:

Parameters of High-alumina Refractory Castable:

| Item | GL-50 | GL-60 | GL-65 | GL-70 | GL-80 | |

| ω(Al₂O₃)/%≥ | 50 | 60 | 65 | 70 | 80 | |

| Bulk Density(g/cm3) ≥ | 110℃*24h | 2.15 | 2.30 | 2.40 | 2.45 | 2.65 |

| Cold Modulus of Rupture/Mpa≥ | 4.0 | 5.0 | 6.0 | 6.0 | 7.0 | |

| Cold Crushing Strength/Mpa≥ | 25 | 30 | 35 | 35 | 40 | |

|

Linear Dimensional Change After Fired (Experimental temperature*3h)% |

±0.8 (1350℃) |

±0.8 (1400℃) |

±0.8 (1500℃) |

|||

Q:What is high alumina castable refractory made of?

A:High alumina castable is primarily composed of bauxite aggregate, alumina cement, silica fume, and refractory additives. The Al₂O₃ content typically ranges from 65% to 85%, depending on the grade.

Q:What is the maximum service temperature of high alumina castable?

A:Depending on its composition, high alumina castable can withstand temperatures between 1500°C and 1700°C, making it suitable for demanding high-temperature environments like rotary kilns and furnace linings.

Q: How is high alumina castable installed?

A:It is usually mixed with water on site and cast or vibrated into place. After curing for 24 hours, a controlled drying and firing process is recommended to reach optimal performance.

Q: Is high alumina castable suitable for steel or cement industries?

A:Yes. It is widely used in cement rotary kilns, steel ladles, tundishes, and furnace walls thanks to its high strength, thermal shock resistance, and abrasion resistance.

Q: Do you offer steel fiber reinforced high alumina castables?

A:Yes, we offer steel fiber reinforced formulations to improve spalling resistance and mechanical strength, especially in environments with severe thermal cycling.

Q: How long is the shelf life of your high alumina castables?

A:When stored in dry conditions and sealed packaging, the shelf life is typically 6–12 months. Avoid exposure to moisture.

Q: Can you customize the formula based on our working conditions?

A:Absolutely. We offer custom formulations tailored to your operating temperature, installation method, and chemical exposure. OEM/ODM service is also available.

Q: What packaging options do you offer?

A:We provide standard 25kg bags and 1000kg jumbo bags with moisture-proof lining. Packaging can be customized with your brand logo for OEM orders.

Q: Do you provide technical support or installation guides?

A:Yes, we offer PDF manuals, video tutorials, and one-on-one technical support for installation, curing, and firing procedures.

Q: Can I get a free sample before placing a bulk order?

A:Yes. We provide free samples (typically 1–2kg) for testing. Please contact our sales team to arrange shipping.

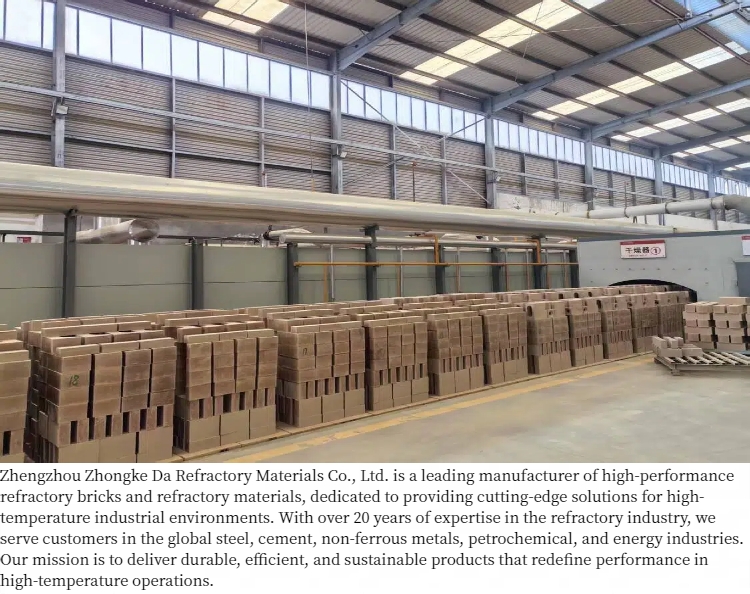

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd