Refractory Clay Castable

Refractory Clay Castable

High Performance | Customizable Formula | Direct Manufacturer

Our Refractory Clay Castables are engineered monolithic solutions designed for superior thermal insulation, exceptional abrasion resistance, and long service life in high-temperature environments. Crafted from carefully selected high-alumina and fire clay aggregates combined with advanced binders, these castables offer outstanding workability for rapid installation and seamless lining of complex furnace geometries where traditional bricks fall short.

Characters of Refractory Clay Castable

•🔥Excellent Thermal Resistance – Withstands temperatures up to 1400–1600°C

•🧱Strong Adhesion & Volume Stability – Reduces cracking and improves service life

•💧Low Water Consumption – Enhances density and strength after setting

•⚙️Easy to Install – Suitable for casting, gunning, or pumping

•🧪Custom Formulas Available – Tailored to your operating conditions

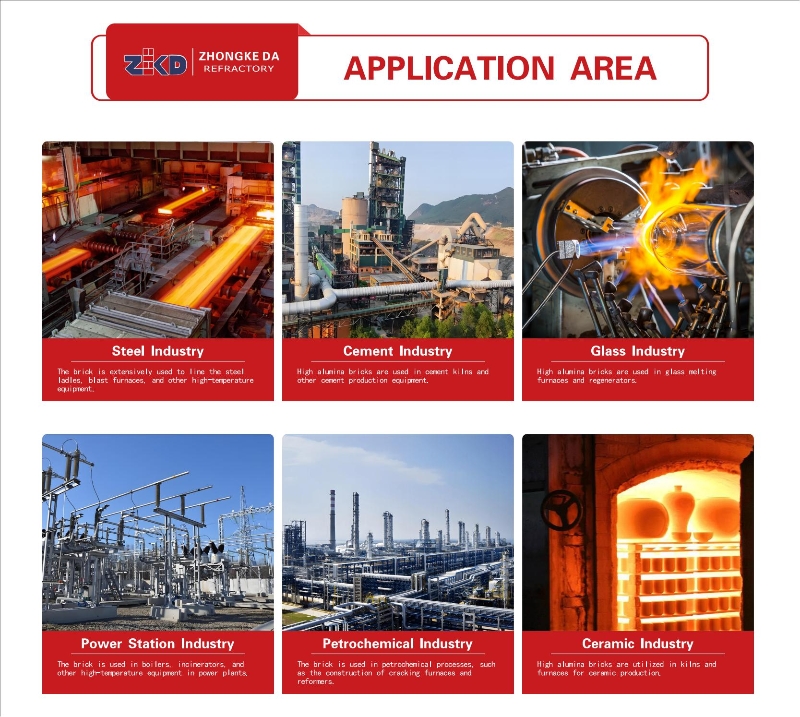

Typical Applications of Refractory Clay Castable

•Furnace hearths, roofs, and walls | •Boiler combustion zones & cyclones | •Ladle backup linings & impact pads | •Incinerator linings | •Kiln inlets, hoods, & transition zones | •Petrochemical heater floors & walls | •Foundry ladles & runners | •Repair & patching of existing refractory structures

Parameters of Refractory Clay Castable

| Item |

NTJ-40 |

NTJ-45 |

|

|

Al₂O₃,(%)≥ |

40 | 45 | |

|

Refractoriness,(℃)≥ |

1640 | 1700 | |

| Bulk density,(g/cm³)≥ | 110℃*24h | 2.05 | 2.10 |

|

Cold Modulus of Rupture,(MPa)≥ |

4.0 | 4.0 | |

|

Cold Crushing Strength,(MPa)≥ |

25 | 25 | |

|

Permanent Linear Change, (%) |

1300℃*3h

±0.8

|

1350℃*3h

±0.8

|

|

Q: What is the typical application of clay castables?

A:They are commonly used in linings for furnaces, kilns, boilers, incinerators, and other high-temperature industrial equipment, especially in areas with medium thermal requirements (typically 1300–1600℃).

Q:What is the service temperature range?

A:Service temperature typically ranges from 1350°C to 1600°C, depending on the formulation and installation.

Q:What is the difference between clay castable and high alumina castable?

A:•Clay castable has lower Al₂O₃ content (usually 35–45%) and is cost-effective, suitable for medium-duty applications.

•High alumina castable contains more Al₂O₃ (≥55%) and is suitable for higher temperatures and more demanding environments.

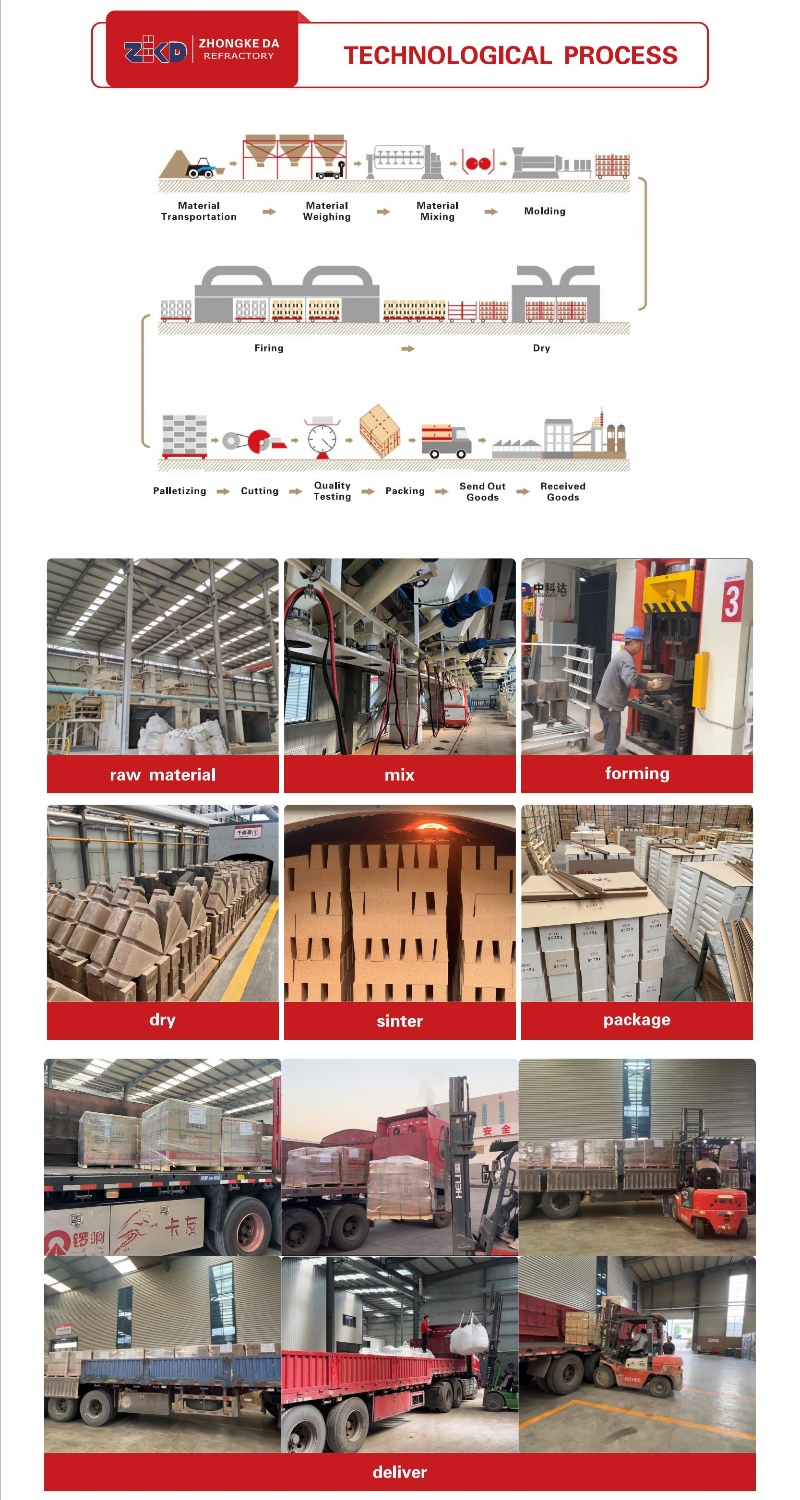

Q:How is refractory castable installed?

A:It can be poured, troweled, or gunned into place. After installation, it needs proper curing and drying before service. We provide technical support and instructions for installation.

Q:Do you offer customized formulations?

A:Yes, we provide OEM & ODM services. Our technical team can adjust the composition based on your furnace design, temperature conditions, and wear requirements.

Q:What is the shelf life of refractory clay castable?

A:Usually 6–12 months if stored in a cool, dry place, away from moisture.

Q:Can I get a sample before bulk order?

A:Yes, free samples are available, and we support small trial orders for testing before full-scale procurement.

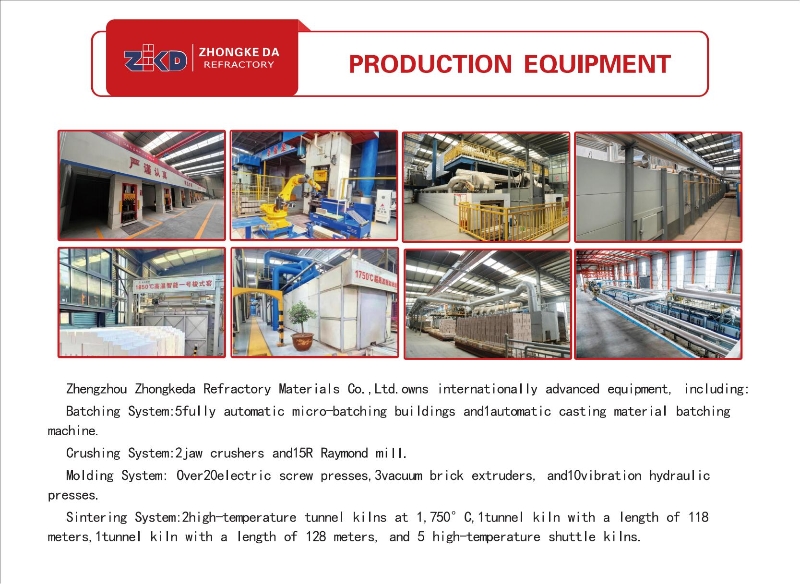

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd