Anchor Bricks

Refractory Anchor Bricks for Industrial Kilns - High-Strength | Custom Sizes | Factory Direct

Anchor bricks are designed for supporting and anchoring ceramic fiber modules, castables, or refractory linings in high-temperature industrial furnaces. Manufactured from high alumina or special refractory materials, these bricks are ideal for kilns, boilers, reformers, and incinerators.

They ensure structural stability and extend the service life of the entire refractory system.

Characters of Anchor Bricks:

•🔥Excellent Thermal Shock Resistance:Withstand rapid temperature changes without cracking or spalling.

•🧱High Mechanical Strength:Reliable support under heavy thermal loads.

•🛠️Custom Shapes & Sizes Available:T-shaped, Y-shaped, L-shaped, etc. – tailored to your project needs.

•🧪Corrosion and Erosion Resistant:Suitable for harsh chemical environments.

•🧯Operating Temperature: Up to 1600°C (2912°F)

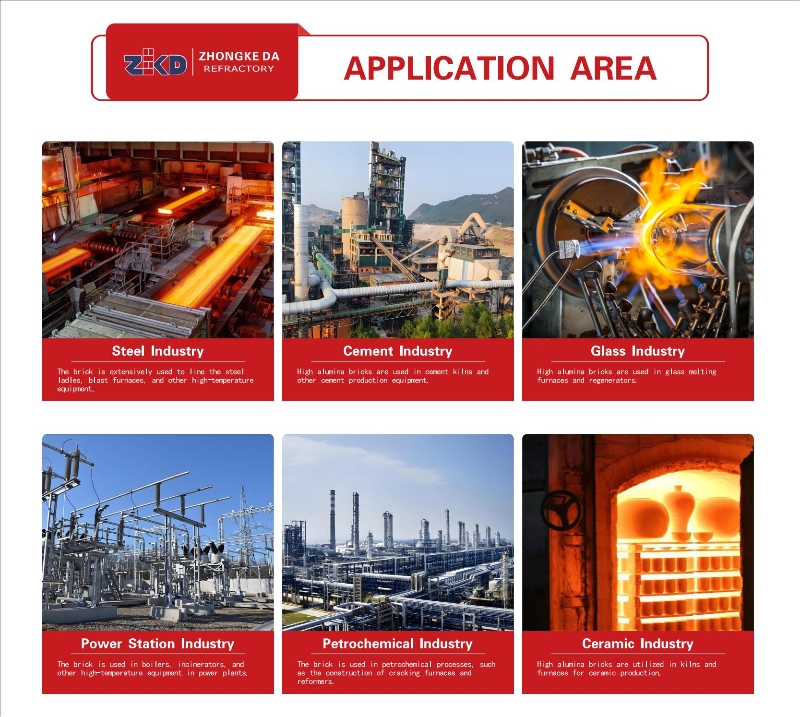

Applicate of Anchor Bricks:

•High-Temperature Furnaces:Lining stabilization in steel/glass furnaces

•Chemical Reactors:Corrosion-resistant anchoring in reactors

•Power Plants:Boiler & incinerator insulation systems

•Cement Kilns:Rotary kiln refractory reinforcement

Parameters of Anchor Bricks:

FAQ:

Item

LM-55

LM-65

LM-75

Al₂O₃(%), ≥

55

65

75

CaO(% )≤

2

2

2

Cold Crushing Strength(MPa), ≥

50

50

55

Tensile Strength(MPa), ≥

4.0

4.1

4.2

Refractoriness under load 0.2MPa( °C), ≥

1450

1500

1520

Apparent Porosity(%), ≤

22(24)

23(24)

21(23)

Bulk Density, g/cm³

2.3

2.35~2.4

2.5~2.6

Heating Permanent Linear Change (1500°Cx2h), %

-0.4~0.2

-0.3~0.2

-0.3~0.2

Q:What are anchor bricks used for?

A:Anchor bricks are used to secure refractory linings, such as castables or ceramic fiber modules, inside industrial kilns, furnaces, or boilers. They help prevent lining collapse, improve mechanical stability, and extend furnace life.

Q:What shapes and sizes are available?

A:We provide a variety of standard shapes like T-shaped, Y-shaped, V-shaped, L-shaped, and also support custom designs based on your furnace structure. Please send us your drawing or specifications.

Q:What material are your anchor bricks made of?

A:Our anchor bricks are made from high alumina, mullite, or zircon-based refractory materials, selected for their high-temperature and corrosion resistance.

Q:How are anchor bricks installed?

A:They are typically mechanically fixed to the steel shell or anchoring mesh using metal anchoring systems, ceramic rods, or mortar bonding. We provide installation guidance and can recommend matching metal anchors or insulation boards.

Q:How do I choose the right anchor brick for my kiln or furnace?

A:Our engineers can help you choose the right model based on:

•Furnace type (rotary kiln, tunnel kiln, incinerator, etc.)

•Lining structure (castable, brick, or fiber module)

•Operating temperature and atmosphere

•Thermal shock requirements

•Load-bearing needs

Simply send us your project details, and we’ll offer a tailored solution.

Q:Can I request samples before placing a bulk order?

A:Yes, we can provide free or paid samples depending on the design and quantity. Freight cost is typically paid by the buyer. Sample lead time is 5–7 days.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd