Refractory Clay Insulation Brick

Fireclay Insulating Brick | Lightweight Thermal Insulation | OEM Manufacturer for High-Temperature Applications

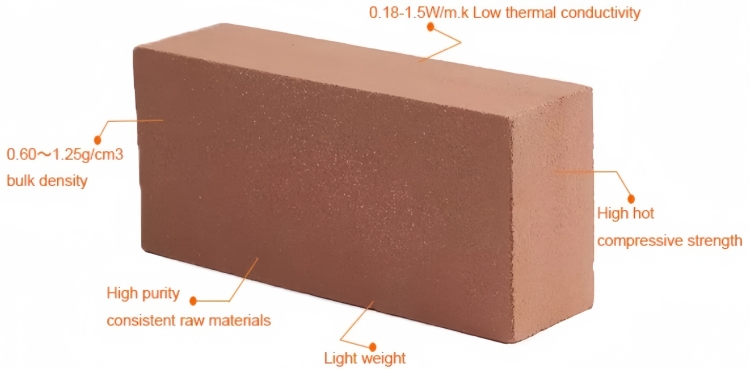

Clay insulating brick is a lightweight thermal insulation material primarily made from refractory clay, specifically designed for medium- to low-temperature industrial equipment (≤1200°C). It offers cost-effectiveness and ease of use as its core advantages.

Characters of Fireclay Insulating Brick:

•🌡️Temperature Resistance: Designed forlong-term use at 800-1200°C and capable of withstanding short-term exposure up to 1300°C, making it ideal for medium- to low-temperature applications.

•❄️Thermal Insulation: Features a thermal conductivity of 0.5–1.0 W/m·K, offering better insulation than standard bricks but lower than high-alumina or mullite bricks.

•💰Cost-Effectiveness: 30%-50% lower cost compared to high-alumina bricks, with readily available raw materials and a simple manufacturing process.

•🏗️Mechanical Strength: Compressive strength ranges from 1–5 MPa, making it suitable only for non-load-bearing insulation layers.

•🧪Chemical Resistance: Resistant to mild acidic environments but requires a protective coating in strong acid or alkaline conditions.

Typical Applications of Fireclay Insulating Brick:

✅ 🔥Metallurgical Industry: Used for annealing furnaces, heat treatment furnace back linings, and hot air duct insulation (≤1100°C).

✅ 🏺Ceramics & Building Materials: Ideal for brick kilns, ceramic kiln cars, and drying kiln insulation layers.

✅ 🛢️Petrochemical Industry: Applied in low-temperature cracking furnaces and storage tank insulation (requires anti-corrosion treatment).

✅ 🏡Residential Use: Suitable for home fireplaces, barbecue grills, and pizza oven linings.

Parameters of Fireclay Insulating Brick:

Item

NG-1.5

NG-1.3

NG-1.2

NG-1.0

NG-0.8

NG-0.6

NG-0.5

Bulk Density (g/cm³)≤

1.5

1.3

1.2

1.0

0.8

0.6

0.5

Cold Crushing Strength (MPa)≥

6

5

4.5

3.5

2.5

1.3

1.0

Permanent Linear Change on Heating/(%)

1400

1350

1350

1300

1250

1200

1150

Thermal conductivity W/(m•K)Mean temperature (350±25)℃ ≤

0.65

0.55

0.50

0.40

0.35

0.25

0.23

FAQ:

Q: What is the maximum temperature resistance of fireclay insulating bricks?

A: Our fireclay insulating bricks can withstand continuous use up to 1250°C (2282°F), making them ideal for industrial kilns, furnaces, and high-temperature equipment.

Q: Can I request customized sizes or shapes?

A: Yes! We offer OEM customization including size, shape (arch/curved/slot), density, and even branded packaging to meet your specific project needs.

Q: What is the minimum order quantity (MOQ)?

A: For regular sizes, our MOQ is usually 1000 pieces. For custom orders, please contact us directly for a tailored solution.

Q: Do your bricks contain asbestos or harmful materials?

A: No. All our bricks are asbestos-free, RoHS and REACH compliant, and safe for industrial and environmental applications.

Q: Can you provide test reports or quality certificates?

A: Absolutely. We provide SGS, ISO 9001, and third-party inspection reports upon request.

Q: What are your packaging and shipping options?

A: We offer export-standard packaging (pallet + stretch film or wooden crate) and support sea, rail, and air shipping. We can also handle FOB/CIF/DDP terms depending on your location.

Q: Do you offer free samples?

A: Yes. Free samples are available for quality testing. Please contact our sales team with your address and courier info.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd