Ceramic Fiber Paper

Ceramic Fiber Paper | High Temperature Insulation | Fireproof, flexible, lightweight

Ceramic fiber paper is a refractory paper product made from ceramic fibers, also known as aluminum silicate fiber paper. It is a high-temperature refractory material, typically composed of inorganic oxide fibers, with main components including Al₂O₃, SiO₂, and ZrO₂. Certain additives are incorporated to enhance its density. ceramic fiber paper exhibits excellent insulation and sealing properties at high temperatures, making it a crucial material in the field of high-temperature thermal insulation.

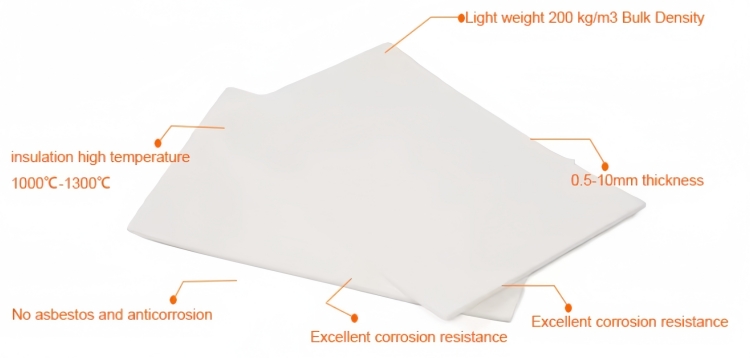

Characters of Ceramic Fiber Paper

• Low thermal conductivity, low thermal capacity, thermal shock resistance.

• Excellent flexibility, tear resistance.

• Asbestos free.

• Corrosion resistance.

• Excellent electrical insulation and sound insulation.

• Excellent mechanical properties.

Applications of Ceramic Fiber Paper

• Thermal short circuit insulation.

• Heat insulating gasket.

• Expansion joint.

• Insulating (sintered resistant) material.

• Blunt sections for domestic heating installations.

• Thermal resistance materials in vehicles (muffler and exhaust device, heat shield).

• Gasket at molten metal.

• Fireproofing.

| Item | Standard Ceramic Fiber Paper | High Pure Ceramic Fiber Paper | High Aluminium Ceramic Fiber Paper | Zirconium Ceramic Fiber Paper | |

| Chemical analysis (%) | Al₂O₃ | 43 | 47 | 55 | 38 |

| SiO₂ | 53 | 51 | 44 | 44 | |

| Fe₂O₃+Ti₂O₃,≤ | 1.2 | 0.3 | 0.3 | 0.2 | |

| CaO+MgO,≤ | 0.3 | 0.3 | 0.3 | 0.2 | |

| NaO+K₂O,≤ | 0.5 | 0.3 | 0.3 | 0.2 | |

| Crganic Content (%) | 5 | ≤5 | ≤5 | ≤5 | |

| Density(kg/m³) | 180-220 | ||||

| Work Temperature(℃) | 1050 | 1150 | 1250 | 1350 | |

| Thickness | 0.5-10mm | ||||

| Size |

40000*1220*1mm,40000*610*1mm,30000*1220*2mm,30000*610*2mm,20000*1220*3mm, 20000*610*3mm,15000*610*4mm,10000*610*5mm |

||||

FAQ:

Q:Are you a manufacturer of ceramic fiber paper?

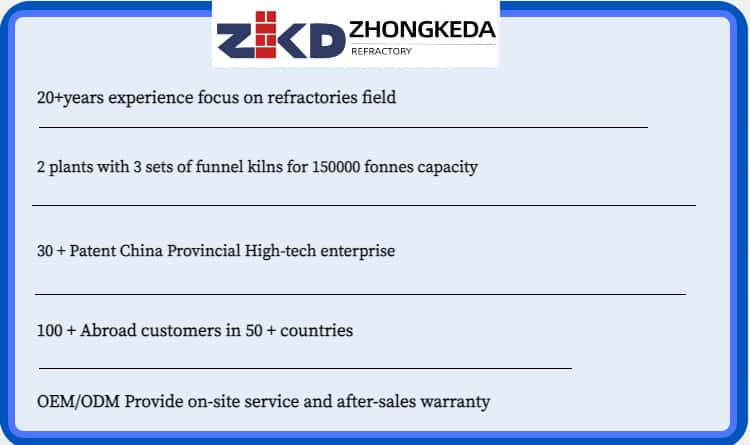

A: Yes, we are a professional manufacturer with years of experience in producing ceramic fiber products. Our factory is equipped with advanced wet-forming production lines and strict quality control systems. Our products are widely exported to Europe, Southeast Asia, the Middle East, and North America.

Q:What is your minimum order quantity (MOQ)? Can I mix different specifications in one order?

A: The MOQ is typically 100 square meters. Mixed specifications in one order are acceptable, especially for sample runs or small-scale trials.

Q:What is the maximum temperature resistance of your ceramic fiber paper?

A: Standard ceramic fiber paper can withstand temperatures up to 1260°C. We also offer high-alumina (up to 1350°C) and zirconia-enhanced types (up to 1430°C) for more demanding applications.

Q:Can I get a sample for testing?

A: Absolutely. We offer free A4-sized samples for performance testing and compatibility evaluation. Samples are typically dispatched within 1–3 working days.

Q:What payment methods do you support?

A: We accept T/T (bank transfer), L/C (letter of credit), PayPal, and Alipay. Other payment options can be discussed if needed.

Q:How is the product packaged for export?

A: Our ceramic fiber paper is packed in moisture-proof plastic bags and reinforced cartons or pallets for safe long-distance transportation. We ensure the packaging is strong enough for sea or air shipping.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd