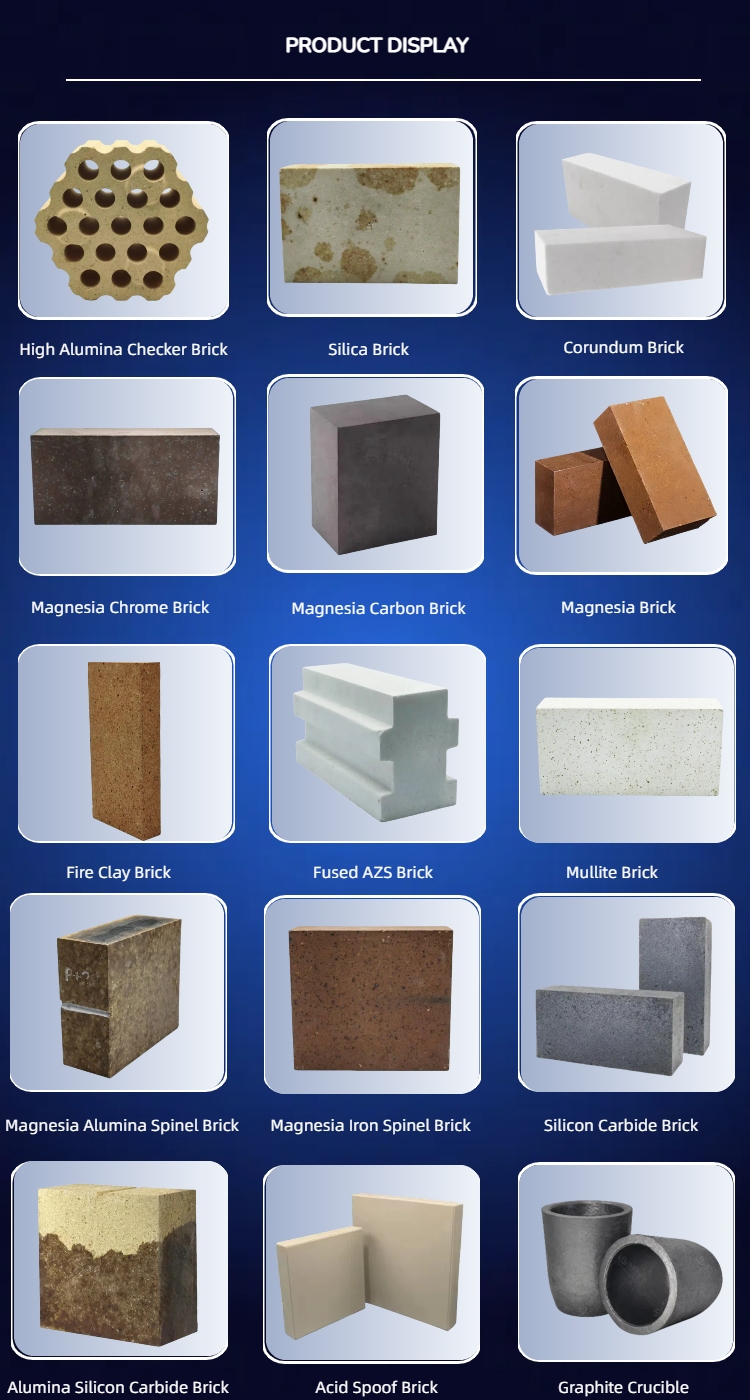

Graphite Crucible

Graphite Crucibles for Metal Melting | High Purity, Thermal Shock Resistant

Graphite crucibles are high-temperature-resistant containers widely used for melting and casting metals such as gold, silver, copper, and aluminum. Made from high-purity graphite and precision processed, they offer excellent thermal conductivity, resistance to thermal shock, and long service life under extreme conditions.

Key Performance Features of Graphite Crucibles:

•🔥High Temperature Resistance:Operates at up to 1800–3000°C in inert atmospheres, significantly higher than traditional ceramic crucibles (≈1600°C).

•⚡Excellent Thermal Conductivity:Thermal conductivity of 50–150 W/m·K, enabling fast and uniform heat transfer for improved melting efficiency.

•🌡️Superior Thermal Shock Resistance:Withstands rapid heating and cooling cycles (ΔT > 1000°C) without cracking — ideal for repeated thermal cycling operations.

•🧪Chemical Inertness:Resistant to acids and alkalis (except strong oxidizing acids); does not react with most molten metals such as aluminum, copper, and gold.

•🛠️Mechanical Strength:Maintains compressive strength of 20–50 MPa at high temperatures. Note: brittle in nature, so avoid mechanical impact.

Applications of Graphite Crucible:

•🔥Metal Smelting:Gold, silver, copper, aluminum in induction or gas furnaces.

•🏭Industrial Casting:Used in non-ferrous foundries, jewelry factories, and precision casting.

•🔬Lab & Research Use:Small-scale alloy testing, high-temp material experiments.

•🌍Vacuum and Inert Gas Furnaces:Ideal for carbon reduction and sintering in oxygen-free environments.

Standard graphite crucible specifications

|

Model |

Upper port outside diameter ±2% |

Thickness |

Lower bottom outside diameter ±2% |

Height ±2% |

|

1# |

67 |

8± 1.0 |

35 | 65 |

| 1.5# | 78 |

10± 1.0 |

60 | 80 |

| 2# | 88 |

10± 1.0 |

62 | 100 |

| 3# | 100 |

12± 1.0 |

75 | 115 |

| 4# | 115 |

12± 1.0 |

85 | 115 |

| 5# | 122 |

13± 1.0 |

85 | 138 |

| 6# | 125 |

14 ± 1.0 |

85 | 155 |

| 41# | 215 |

19~ 21.5 |

150 | 290 |

| 45# | 250 |

19~ 21.5 |

180 | 295 |

| 70# | 285 |

19~ 21.5 |

215 | 245 |

| 80# | 310 |

20~ 22.5 |

210 | 370 |

| 90# | 320 |

21~ 23.5 |

230 | 385 |

| 100# | 314 |

21~ 23.5 |

220 | 408 |

| 200# | 400 |

23~ 25.5 |

290 | 475 |

| 260# | 416 |

24~ 26.5 |

250 | 585 |

| 300# | 452 |

26~ 29 |

310 | 580 |

| 360# | 462 |

28~ 31 |

342 | 674 |

| 390# | 530 |

28~ 31 |

410 | 560 |

| 400# | 515 |

29~ 32 |

340 | 600 |

| 420# | 515 |

29~ 32 |

330 | 673 |

| 440# | 620 |

29~ 32 |

340 | 500 |

| 450# | 516 |

32~ 35 |

340 | 710 |

| 530# | 580 |

31~ 34 |

330 | 635 |

|

560# |

590 |

33~ 36 |

330 | 690 |

|

570# |

620 |

33~ 36 |

335 | 570 |

|

580# |

545 |

33~ 36 |

317 | 750 |

|

610# |

607 |

34~ 38 |

350 | 630 |

|

680# |

585 |

34~ 38 |

330 | 760 |

|

690# |

600 |

34~ 38 |

330 | 805 |

|

700# |

615 |

34~ 38 |

350 | 758 |

|

840# |

700 |

35~ 39 |

470 | 675 |

|

950# |

720 |

37~ 41 |

300 | 740 |

|

970# |

720 |

34~ 38 |

470 | 730 |

|

1100# |

715 |

35~ 39 |

478 | 846 |

|

1150# |

855 |

42~ 46 |

340 | 677 |

|

1200# |

780 |

36~ 40 |

450 | 752 |

|

1250# |

725 |

36~ 40 |

470 | 905 |

|

1500# |

784 |

37~ 41 |

450 | 890 |

|

1700# |

778 |

40~ 44 |

442 | 1050 |

|

2500# |

880 |

44~ 48 |

350 | 1150 |

FAQ:

Q:What is a graphite crucible used for?

A:Graphite crucibles are primarily used for melting and casting metals such as gold, silver, copper, aluminum, and brass. Their excellent thermal conductivity and resistance to high temperatures make them ideal for foundry, metallurgy, jewelry making, and laboratory applications.

Q: What materials are your graphite crucibles made of?

A: Our crucibles are made from high-purity, fine-grain graphite reinforced with special binders to ensure excellent thermal shock resistance, durability, and longevity even in extreme conditions.

Q:What sizes and shapes are available?

A:We offer a wide range of sizes, from small crucibles (e.g., 1kg capacity) for jewelry melting to large industrial crucibles (50kg+). Shapes include cylindrical, conical, and special custom forms. Please contact us for a catalog or customization service.

Q:Can I order custom crucibles for my specific furnace or application?

A:Yes. We provide OEM & ODM services. Custom size, shape, wall thickness, and material density are available to meet your specific industrial or laboratory requirements.

Q:Are your crucibles reusable? How long do they last?

A:Yes, graphite crucibles are reusable. Their lifespan depends on the metal type, melting temperature, frequency of use, and handling. With proper care, they can last for dozens of melting cycles.

Q: How should I maintain and store the crucibles?

A:Always preheat before use to prevent thermal shock.

Avoid sudden temperature changes.

Store in a dry, cool place away from moisture.

Do not use with strong oxidizing agents at high temperatures unless protected by an inert atmosphere.

Q: What is your MOQ and lead time for bulk orders?

A:MOQ: 50–100 units depending on size and type.

Lead time: Typically 7–15 business days for standard orders; custom orders may take longer.

Q:Do you provide international shipping?

A:Yes, we ship worldwide. We offer flexible shipping solutions including sea freight, air freight, and express courier (DHL/UPS/FedEx). Our logistics team can help you choose the most cost-effective method.

Q:Can you provide samples for testing before bulk purchase?

A:Yes. Sample orders are welcomed. Please contact us with your specifications, and we’ll arrange a sample shipment.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd