Calcium Silicate Board

Calcium silicate board is a new type of building material made from siliceous materials (such as quartz powder), calcareous materials (such as lime powder), and reinforcing fibers as the main raw materials. It is produced through high-temperature and high-pressure steam curing. Calcium silicate board features excellent fire resistance, moisture and mold resistance, as well as being lightweight yet high in strength. It is widely used in the construction, petroleum, electric power, and chemical industries for insulation and thermal protection in partition walls, curtain walls, roofing, and enclosure structures.

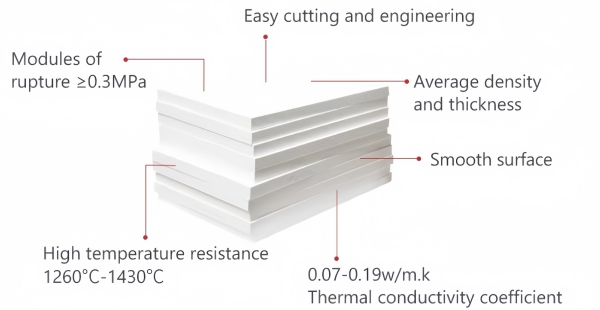

Character of Calcium Silicate Board

•🔥Fire Resistance:Class A1 non-combustible, fire resistance rating of 1–4 hours (depending on thickness)

•⚖️Lightweight:Density of 1.2–1.5 g/cm³

•🛠️Construction Efficiency:Dry installation (easy to cut and drill), reduces construction time by 50%

•🌿Energy Saving & Eco-Friendly:Asbestos-free and pollution-free, thermal conductivity of 0.2 W/m·K (for effective insulation and energy saving)

•💰Overall Cost Efficiency:Low transportation and installation cost, maintenance-free, service life over 30 years

Typical Application of Calaium Silicate Board

•Lightweight Insulation Layer for Kiln Linings:Partially replaces refractory bricks to reduce weight and save 10–15% in energy. Excellent thermal shock resistance with no cracking. Heat resistance above 1100°C.

•Fire Protection for Steel Structures:Encloses steel columns/beams with 12–20mm boards, offering 2–3 hours of fire resistance. VOC-free and certified to EN 13501 standards.

•High-Temperature Piping:Custom curved boards fit closely around pipelines. Acid and alkali resistant, no need for additional support brackets.

•Special Applications:Fireproof compartments in ships and partition walls in cleanrooms.

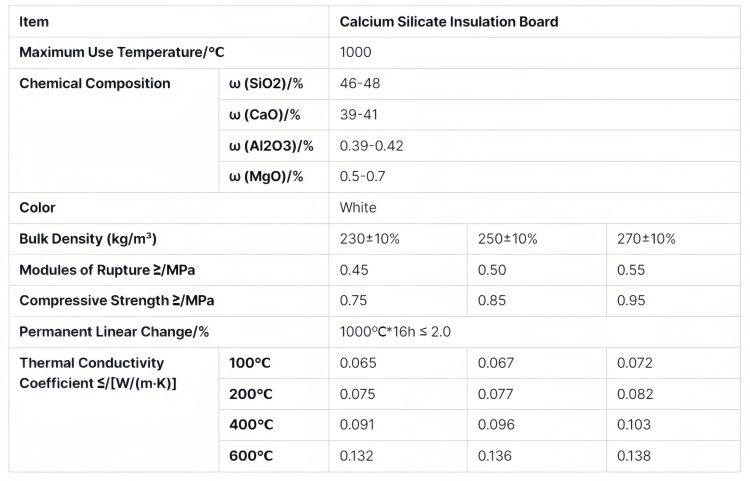

Parameters of Calcium silicate board

Q:What is calcium silicate board made of?

A:Calcium silicate board is made from siliceous materials (like quartz powder), calcareous materials (like lime powder), and reinforced fibers. It is produced through high-temperature and high-pressure steam curing.

Q:Is your calcium silicate board asbestos-free?

A:Yes, our boards are 100% asbestos-free and environmentally friendly. They comply with international safety and environmental standards such as CE and ISO.

Q:Is the board easy to install?

A:Absolutely. The board supports dry construction, and can be easily cut, drilled, nailed, or painted using standard tools. It reduces construction time by up to 50%.

Q:What thicknesses are available?

A:Common thicknesses include 6mm, 9mm, 12mm, 15mm, and 20mm, but custom sizes can be manufactured upon request.

Q:How is the product packaged for export?

A:Boards are packed on wooden pallets with plastic wrap or in wooden crates for safe international shipping. OEM packaging is also available.

Q:Do you offer OEM or custom manufacturing?

A:Yes, we provide OEM/ODM services, including custom dimensions, densities, surface treatments, and branding options.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd