Silicon Insulation Brick

Silica insulating bricks are lightweight thermal insulation refractory materials with silicon dioxide (SiO₂) as the main component (≥92%). They are formed through high-temperature sintering or chemical bonding, creating a porous structure that combines low thermal conductivity with high-temperature resistance. These bricks serve as a key material for energy saving and consumption reduction in industrial furnaces.

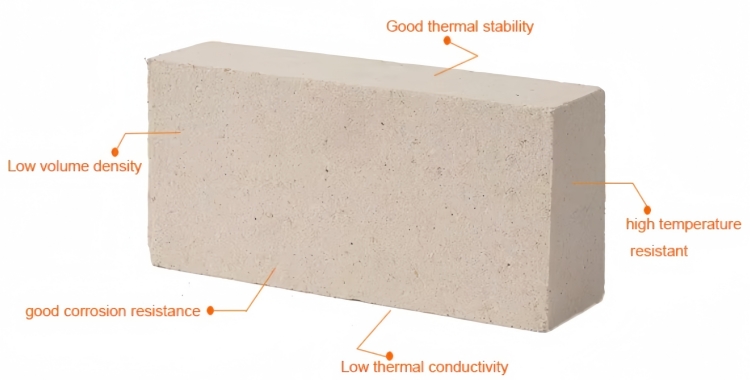

Key Advantages of Silica Insulating Brick:

📉 Ultra-low thermal conductivity for significant energy savings.

🔥 High-temperature resistance, suitable for extreme environments.

🧪 Excellent acid resistance, extending service life.

⚖️ Lightweight yet strong, reducing structural load.

🌿 Eco-friendly, cost-effective, and safe, with flexible customization options.

Application Scenarios of Silica Insulating Brick:

1.🔥High-Temperature Industrial Kilns

•🫙Glass Industry: Insulation layer for glass melting furnace crowns and breast walls (reduces heat loss by 30%).

•🏺Ceramics Industry: Lining for roller kilns and tunnel kilns (shortens heating time by 20%).

•⚒️Metallurgical Industry: Insulation for coke oven doors and ladle covers (reduces surface temperature to below 80℃).

2.🌱Energy & Environmental Protection Equipment

•⚡Power Plant Boilers: Furnace wall insulation (reduces heat dissipation loss to ≤2%).

•🗑️Waste Incinerators: Insulation for secondary combustion chambers (resistant to acidic flue gas corrosion).

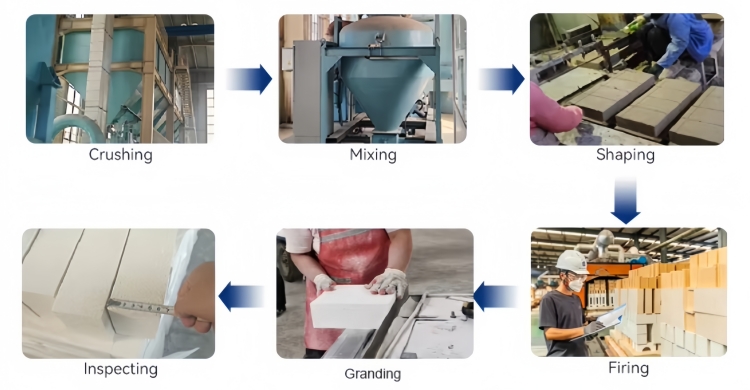

Production Process of Silica insulating bricks:

Technical Specifications of Silica insulating brick:

|

Item |

GGR-1.00 |

GGR-1.10 |

GGR-1.15 |

GGR-1.20 |

|

SiO₂ (%)≥ |

91 |

91 |

91 |

91 |

|

Bulk Density/(g/cm³)≥ |

1.00 | 1.10 | 1.15 | 1.20 |

|

Cold Crushing Strength/(Mpa)≥ |

2.0 | 3.0 | 5.0 | 5.0 |

|

Reheating linear change≤(1550℃,2h) |

/ | / | 0.5 | 0.5 |

|

Reheating linear change≤(1450℃,2h) |

0.5 |

0.5 | / | / |

|

0.1MPa Refractoriness under load start temperature/(℃)≥ |

1400 | 1420 | 1500 | 1520 |

|

Thermal conductivity W/(m•K)Mean temperature 350±10℃ ≤ |

0.55 | 0.60 | 0.65 | 0.70 |

Q:What is the maximum operating temperature?

A:Our standard silica insulating bricks can withstand continuous operating temperatures of up to 1260°C (2300°F). Please contact us for custom options for higher temperature resistance.

Q:Can I request custom sizes or shapes?

A:Absolutely. We provide OEM customization, including special shapes like arch bricks, wedge bricks, tongue-and-groove, and more.

Q:Do you provide technical data sheets and certifications?

A:Yes, we provide SGS test reports, RoHS certificates, and technical data sheets (TDS) for all product lines upon request.

Q:Can I get a free sample before bulk purchase?

A:Yes! We offer free samples for product evaluation and testing. Please contact us to arrange shipping details.

Q:Do you accept bulk wholesale orders internationally?

A:Yes, we specialize in bulk manufacturing and global B2B supply. Our bricks are exported to over 30 countries with secure packaging and fast delivery.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd