Corundum Mullite Brick

Corundum Mullite Bricks - High-Performance Refractory Solutions for Demanding Industrial Applications

Corundum-Mullite Brick is a high-quality shaped refractory material made primarily from corundum (α-Al₂O₃) and mullite (3Al₂O₃·2SiO₂), with mullite and corundum as the main crystalline phases. It exhibits excellent high-temperature stability, thermal shock resistance, and chemical corrosion resistance, making it widely used in metallurgy, building materials, and chemical industries for high-temperature equipment.

Characters of Corundum Mullite Brick:

•🔥High-Temperature Performance: Can be used continuously at 1600–1800°C, maintaining high strength at elevated temperatures.

•⚡Thermal Shock Resistance: The low thermal expansion coefficient (from the mullite phase) helps reduce cracks caused by sudden temperature changes.

•🛡️Corrosion Resistance: Strong resistance to acidic slag, alkaline slag, and molten metal erosion.

•📏Low Creep Rate: Maintains shape at high temperatures, preventing deformation and extending furnace service life.

Main Application of Corundum-Mullite Brick:

•🏭Steel Industry: Lining of reheating furnaces, walking beam furnaces

•🧪Ceramic Industry: Kiln furniture, tunnel kilns

•🔥Glass Industry: Glass tank regenerators, feeders

• 🏗 Petrochemical Industry: Cracking furnaces, reformer linings

• ⚙ Power Plants: Waste incinerators, boiler linings

Parameters of Corundum-Mullite Brick:

Item

GMZ-88

GMZ-85

GMZ-80

GMZ-75

Al₂O₃, (%)≥

88

85

80

75

Fe₂O₃, (%)≤

0.8

1.0

1.0

1.2

Apparent Porosity, (%)≤

15(17)

16(18)

18(20)

18(20)

Bulk Density, (g/cm³)≥

3

2.85

2.75

2.6

Cold Crushing Strength, (Mpa)≥

120

100

100

80

0.2Mpa Refractoriness Under Load (T0.6 ℃)≥

1700

1680

1650

1650

Permanent Linear Change On Reheating,%(1500℃*2h)

-0.1⁓0.1

-0.1⁓0.1

-0.2⁓0.2

-0.2⁓0.2

FAQ:

A: Corundum Mullite Bricks offer superior high-temperature resistance, better thermal shock resistance, lower creep rates at high temperatures, and outstanding corrosion resistance to slags and chemicals.

Q: In which industries are Corundum Mullite Bricks commonly used?

A: They are widely used in steel reheating furnaces, ceramic kilns, glass furnaces, petrochemical cracking furnaces, waste incinerators, and other high-temperature industrial kilns.

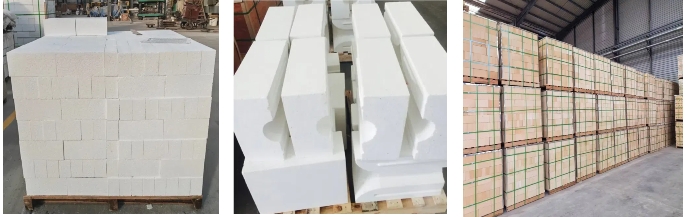

Q: Can you customize the size and shape of Corundum Mullite Bricks?

A: Yes, we offer customized shapes, dimensions, and compositions based on your furnace design or specific application needs.

Q: What is the maximum service temperature of Corundum Mullite Bricks?

A: Our Corundum Mullite Bricks can operate steadily at temperatures up to 1800°C, depending on the specific grade.

Q: How is the thermal shock resistance of Corundum Mullite Bricks?

A: They exhibit excellent thermal shock resistance, capable of withstanding rapid temperature changes, making them ideal for demanding thermal cycling conditions.

Q: Do you provide technical support for material selection and installation?

A: Yes, our experienced technical team can provide guidance on material selection, lining design, and installation methods to help optimize your furnace performance.

Q: What is your typical lead time for Corundum Mullite Brick orders?

A: Lead time usually ranges from 15 to 30 days, depending on order quantity and customization requirements.

Q: What certifications do your Corundum Mullite Bricks meet?

A: Our products are manufactured under strict quality systems and can be supplied with ISO certifications, chemical analysis reports, and third-party inspection certificates if needed.

Q: How are the bricks packaged for international shipment?

A: Bricks are securely packed on fumigated wooden pallets with waterproof wrapping to ensure safe handling and delivery.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd