Service

1.Refractory for Dry Quenching Coke Ovens

Engineered for CDQ systems: high thermal shock resistance, wear and corrosion resistance, high-temperature strength, and dimensional accuracy — ensuring long-life and safe operation.

Main Types of Refractory Bricks for CDQ Furnaces:

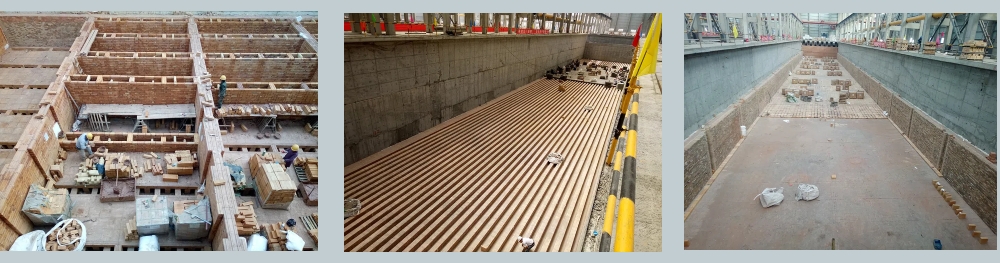

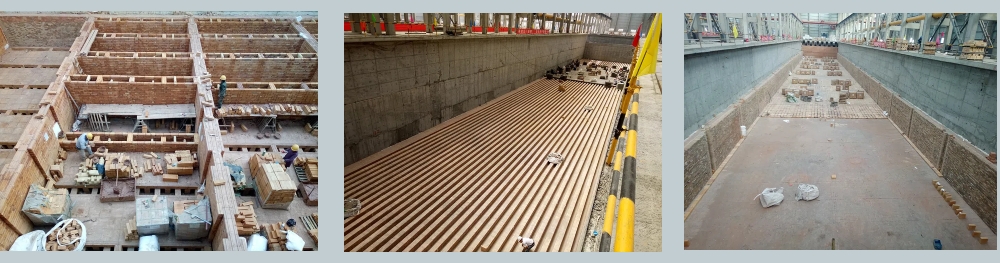

COQ Coke Oven Case:

2.Refractory for Iron Making

Refractory materials for ironmaking must offer high-temperature resistance, thermal shock resistance, corrosion resistance, and dimensional precision. Material selection should be tailored to specific operating conditions to ensure extended equipment lifespan and cost-effective performance.

Refractory Applications & Types in Steelmaking:

Iron Making Case:

3.Refractory for Carbon Industry

In the carbon industry, refractory materials must focus on ultra-high temperature resistance, reduction resistance, and anti-carbon penetration. Customized material selection based on equipment conditions—combined with material innovation and structural optimization—enables efficient, long-lasting, and low-consumption operation of industrial systems.

Commonly used refractory materials in the carbon industry and their performance:

Carbon industry case

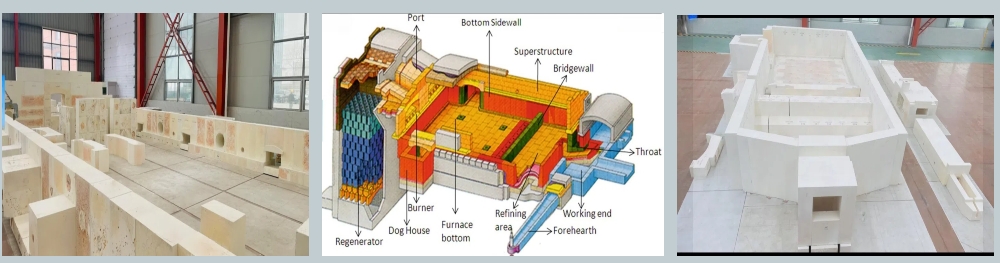

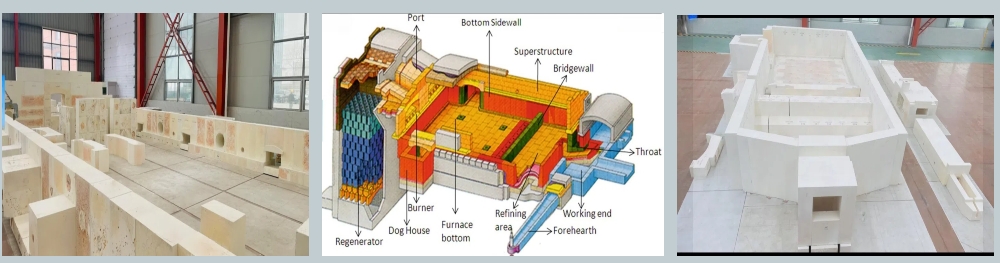

4.Refractory for Glass Industry

Refractories for the glass industry must prioritize corrosion resistance, low contamination, and high stability. Material selection should be tailored to specific glass types (soda-lime, borosilicate, lead glass, etc.) and furnace structures. Through material innovation and structural optimization, furnace lifespan can be significantly extended (from 5 to 10 years), while reducing energy consumption and production costs.

Common Types and Properties of Refractories for the Glass Industry

Glass Industry Case

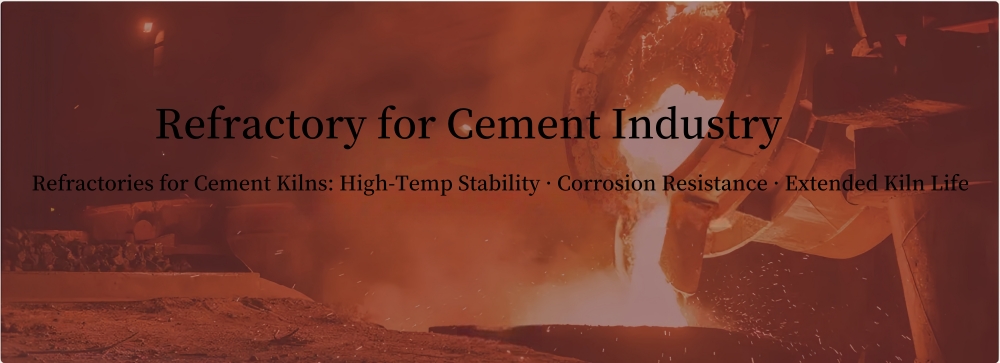

5.Refractory for Cement Industry

Refractories for cement kilns must focus on spalling resistance, high-temperature durability, and chemical corrosion resistance. Material selection should be customized based on kiln type and process conditions (e.g., high-sulfur fuels, alternative fuels). Through material innovation and intelligent maintenance, kiln lining lifespan can be significantly extended (from 1 year to over 3 years), reducing refractory cost per ton of cement by more than 25%.

Common Refractories for Cement Kilns and Their Properties

Cement Kiln Industry Case:

Engineered for CDQ systems: high thermal shock resistance, wear and corrosion resistance, high-temperature strength, and dimensional accuracy — ensuring long-life and safe operation.

Main Types of Refractory Bricks for CDQ Furnaces:

|

Type |

Composition |

Typical Application Area |

Key Advantages |

|

Alumino-Silicate Refractory Brick |

Al₂O₃ (50–70%) + SiO₂ |

Pre-chamber, low-temperature cooling zone |

Cost-effective, moderate thermal shock resistance, suitable for areas with minimal temperature fluctuations |

|

Silicon Carbide–Corundum Composite Brick |

SiC (50–80%) + Al₂O₃ |

Annular flue, high-temperature cooling section |

Excellent thermal conductivity and abrasion resistance, strong resistance to CO corrosion |

|

Mullite-Bonded Silicon Carbide Brick |

SiC + 3Al₂O₃·2SiO₂ (Mullite) |

High-temperature gas inlet, coke flow zone |

Exceptional thermal shock resistance, high resistance to coke erosion |

|

Silicon Nitride–Bonded Silicon Carbide Brick |

SiC + Si₃N₄ |

Coke impact zones (e.g. inclined chute) |

Ultra-high mechanical strength (>60 MPa), excellent impact resistance |

|

Chrome Corundum Brick |

Al₂O₃ (≈90%) + Cr₂O₃ |

High thermal load zones (e.g. combustion chamber) |

High refractoriness (>1600°C), excellent resistance to alkali vapor corrosion |

2.Refractory for Iron Making

Refractory materials for ironmaking must offer high-temperature resistance, thermal shock resistance, corrosion resistance, and dimensional precision. Material selection should be tailored to specific operating conditions to ensure extended equipment lifespan and cost-effective performance.

Refractory Applications & Types in Steelmaking:

|

Basic Oxygen Furnace (BOF) |

|||

|

Application Area |

Refractory Type |

Key Composition |

Performance Advantages |

|

– Furnace Lining |

Magnesia-Carbon Brick (MgO–C) |

MgO (70–85%) + Graphite (10–20%) |

Excellent slag resistance (high MgO), oxidation resistance (graphite coating), and superior thermal shock resistance. |

|

– Trunnion Area |

Magnesia-Calcium Brick (MgO–CaO) |

MgO (60–75%) + CaO (15–25%) |

Resists high-basicity slag corrosion and reduces slag splashing adhesion. |

|

– Taphole |

Alumina–Silicon Carbide Brick (Al₂O₃–SiC) |

Al₂O₃ (≈70%) + SiC (≈20%) |

Withstands high-temperature molten steel erosion and offers strong thermal shock resistance. |

|

Electric Arc Furnace (EAF) |

|||

|

Application Area |

Refractory Type |

Key Composition |

Performance Advantages |

|

– Furnace Wall / Bottom |

Magnesia-Carbon Brick (MgO–C) |

MgO (75–90%) + Graphite (8–15%) |

Excellent resistance to electric arc heating (>1700°C) and oxidative slag attack. |

|

– Furnace Roof |

High Alumina Brick |

Al₂O₃ (80–90%) |

Resists high-temperature gas erosion and offers good volume stability. |

|

– Hotspot Area |

Gunning Mix |

MgO / Al₂O₃ + Binder |

Convenient repair material with good adherence, used for thermal stress zones. |

| Ladle | |||

|

Application Area |

Refractory Type |

Key Composition |

Performance Advantages |

|

– Working Lining |

Alumina-Magnesia-Carbon Brick (Al₂O₃–MgO–C) |

Al₂O₃ (60–70%) + MgO (10–15%) + C |

Resists slag attack (MgO), thermal shock (C), and steel penetration. |

|

– Slag Line Area |

Magnesia-Carbon Brick (MgO–C) |

MgO (80–90%) + Graphite (10–15%) |

Excellent resistance to high-basicity slag; extends slag line life. |

|

– Porous Plug (Bottom) |

Alumina–Spinel Brick (Al₂O₃–Spinel) |

Al₂O₃ (≈85%) + MgAl₂O₄ (Spinel) |

High permeability, strong resistance to steel infiltration, ensures uniform argon blowing. |

| Tundish | |||

|

Application Area |

Refractory Type |

Key Composition |

Performance Advantages |

|

– Working Lining |

Magnesia-Calcia Coating (MgO–CaO) |

MgO (50–70%) + CaO (20–30%) |

High CaO reactivity adsorbs inclusions, improving steel cleanliness. |

|

– Dam/Weir |

Mullite Brick |

3Al₂O₃·2SiO₂ |

Excellent thermal shock resistance; reduces steel turbulence. |

|

Continuous Casting (CCM) |

|||

|

Application Area |

Refractory Type |

Key Composition |

Performance Advantages |

|

– Submerged Entry Nozzle (SEN) |

Zirconia-Carbon Material (ZrO₂–C) |

ZrO₂ (60–75%) + C (20–30%) |

Inert ZrO₂ resists steel erosion and prevents Al₂O₃ clogging. |

|

– Ladle Shroud / Stopper Rod |

Alumina-Carbon Material (Al₂O₃–C) |

Al₂O₃ (70–80%) + C (15–20%) |

Withstands molten steel flow and thermal shocks effectively. |

3.Refractory for Carbon Industry

In the carbon industry, refractory materials must focus on ultra-high temperature resistance, reduction resistance, and anti-carbon penetration. Customized material selection based on equipment conditions—combined with material innovation and structural optimization—enables efficient, long-lasting, and low-consumption operation of industrial systems.

Commonly used refractory materials in the carbon industry and their performance:

|

Material Type |

Main Components |

Application Area |

Core Performance Advantages |

|

High-Purity Graphite Brick |

C ≥ 99.9% |

Lining of graphitization furnaces |

Exceptional thermal stability (up to 3000°C), resistance to CO reducing atmosphere |

|

Silicon Carbide Brick (SiC) |

SiC ≥ 90% |

Firing flue walls, exhaust ducts |

High thermal conductivity (15–25 W/m·K), excellent wear and thermal shock resistance |

|

Silicon Nitride Bonded SiC Brick |

SiC (70–80%) + Si₃N₄ |

Kiln car bearing plates, electrode supports |

Ultra-high strength (>100 MPa), resistance to mechanical impact |

|

Fused Corundum-Mullite Brick |

Al₂O₃ (70%) + 3Al₂O₃·2SiO₂ (Mullite) |

Insulating layer of carburation furnaces |

Excellent thermal shock resistance (>30 cycles), low thermal conductivity (<1.5 W/m·K) |

|

Alumina Hollow Ball Brick |

Al₂O₃ ≥ 99% (hollow sphere structure) |

Outer insulation of carbon fiber furnaces |

Ultra-lightweight (density 0.8–1.2 g/cm³), outstanding high-temperature insulation |

|

Self-bonded SiC Castable |

SiC (75%) + Silica Sol Binder |

Complex shape repairs |

Rapid installation, resistance to asphalt volatile infiltration |

4.Refractory for Glass Industry

Refractories for the glass industry must prioritize corrosion resistance, low contamination, and high stability. Material selection should be tailored to specific glass types (soda-lime, borosilicate, lead glass, etc.) and furnace structures. Through material innovation and structural optimization, furnace lifespan can be significantly extended (from 5 to 10 years), while reducing energy consumption and production costs.

Common Types and Properties of Refractories for the Glass Industry

|

Material Type |

Main Components |

Application Area |

Key Advantages |

Max. Service Temp. |

|

Fused Cast AZS Brick |

ZrO₂ (33–41%) + Al₂O₃ + SiO₂ |

Glass contact zones (melter walls, throat) |

Excellent corrosion resistance, low glass contamination |

1700°C |

|

α-β Alumina Brick |

Al₂O₃ ≥99% (mainly β-Al₂O₃ phase) |

Superstructure, breast wall |

Alkali vapor resistance, outstanding volume stability |

1800°C |

|

Silica Brick |

SiO₂ ≥93% |

Crown (melter dome) |

High hot strength, cost-effective |

1650°C |

|

Magnesia-Alumina Spinel |

MgO 30% + Al₂O₃ 70% |

Regenerator checkers, sidewalls |

Excellent thermal shock resistance, alkali dust resistance |

1500°C |

|

Mullite Brick |

3Al₂O₃·2SiO₂ |

Feeder channel, annealing lehr |

Thermal shock resistance, low thermal conductivity (1.5–2.0 W/m·K) |

1500°C |

|

Dense Chrome Brick |

Cr₂O₃ ≥95% |

Specialty glass furnaces (e.g., opal glass) |

High resistance to boron/fluorine corrosion, acid glass stability |

1750°C |

5.Refractory for Cement Industry

Refractories for cement kilns must focus on spalling resistance, high-temperature durability, and chemical corrosion resistance. Material selection should be customized based on kiln type and process conditions (e.g., high-sulfur fuels, alternative fuels). Through material innovation and intelligent maintenance, kiln lining lifespan can be significantly extended (from 1 year to over 3 years), reducing refractory cost per ton of cement by more than 25%.

Common Refractories for Cement Kilns and Their Properties

|

Material Type |

Main Components |

Application Area |

Key Advantages |

Max Temp |

|

Magnesia-Alumina Spinel Brick |

MgO 20–30% + Al₂O₃ 70–80% |

Sintering & Transition Zone (Rotary Kiln) |

Excellent clinker resistance, superior anti-spalling |

1600°C |

|

High Alumina Brick |

Al₂O₃ 60–80% |

Preheater, Calciner |

Alkali & sulfur resistance, cost-effective |

1500°C |

|

Silicon Carbide Brick |

SiC ≥85% |

Cooler Hot Zone, Kiln Mouth |

Exceptional wear resistance (HV≥2500), thermal shock resistant |

1400°C |

|

Anti-Spalling Castable |

Al₂O₃ 70% + MgO 10% |

Kiln Mouth, Tertiary Air Duct |

Fast installation, thermal shock resistance, anti-build-up |

1450°C |

|

SiC-Mullite Brick |

SiC 30% + Mullite (3Al₂O₃·2SiO₂) |

Preheater Cone, Calciner |

Dual resistance: alkali-sulfur & abrasion |

1350°C |

|

Insulating Brick |

Al₂O₃ 40–50% + Hollow Ball Structure |

Kiln Outer Layer Insulation |

Low thermal conductivity (≤1.0 W/m·K), energy-saving |

1200°C |

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd