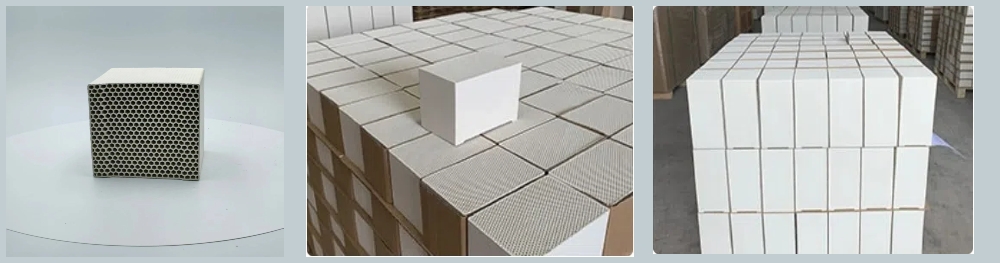

Honeycomb Ceramic

Honeycomb Ceramic | High-Performance Catalyst Support & Regenerative Media

Honeycomb Ceramic is a special ceramic material characterized by its regular honeycomb-like porous structure, from which its name is derived. Manufactured through precision molding and high-temperature sintering, it features a high specific surface area, excellent thermal stability, low thermal expansion coefficient, and strong chemical inertness. It is widely used in environmental protection, energy, and chemical industries.

•High Specific Surface Area:The honeycomb structure provides a large contact area for gas-solid reactions, significantly boosting catalytic efficiency.

•Excellent Thermal Shock Resistance:Withstands rapid temperature changes (>100 cycles at 1100°C to cold water) without cracking or degrading.

•Low Thermal Expansion Coefficient:Maintains structural stability under high-temperature operations (≤ 2.0×10⁻⁶ /°C).

•Superior Mechanical Strength:Engineered for durability and resistance to high airflow pressures in demanding industrial environments.

•Customizable Cell Density (10–600 CPSI):Available in a wide range of configurations to meet specific flow rate and reaction requirements.

•Environmentally Friendly Material:Made from high-purity cordierite, mullite, or alumina—non-toxic and recyclable.

•Low Pressure Drop:Optimized geometry ensures smooth gas flow and energy-efficient operation.

•Chemical Stability:Resistant to corrosion and erosion in acidic or basic exhaust gas conditions.

Applications of honeycomb ceramic:

•♻️RTO (Regenerative Thermal Oxidizer) for VOC removal

•🚗Automotive Three-Way Catalytic Converters

•🏭SCR Systems for NOx reduction

•🔥High-Temperature Heat Storage Media

•🌫️Waste Gas Treatment in Metallurgy & Chemical Industries

Parameters of honeycomb ceramic:

|

Material |

Loose Cordierite |

Dense Cordierite |

Cordierite Mullite |

Mullite |

Corundum Mullite |

|

Al₂O₃, % |

33-35 |

35-37 |

33-35 |

59-61 |

69-72 |

|

SiO₂, % |

48-50 |

48-50 |

48-51 |

37-39 |

28-30 |

|

Thermal Expansion (Room Temp.-1000%)×10-6/℃ |

1.5-1.8 |

2-2.5 |

2.0-3.0 |

4.2-5.0 |

4.5-5.2 |

|

Thermal Capacity(Room Temp.-1000℃), J/kg |

750-900 |

800-1200 |

1100-1300 |

1100-1300 |

1300-1400 |

|

Heat Shock Resistance ℃ |

300 |

250 | 300 | 230 | 260 |

|

Softening Temperature℃ |

1280 | 1350 | 1400 | 1630 | 1680 |

|

Refractoriness ℃ |

1360 |

1410 | 1480 | 1750 | 1790 |

|

Max Service Temperature |

1200 | 1300 | 1350 |

>1550 |

>1600 |

Q:What materials are your honeycomb ceramics made of?

A:We offer honeycomb ceramics made from Cordierite, Mullite, and Alumina. The material selection depends on your application temperature, chemical environment, and required thermal properties.

Q:Can I customize the cell density (CPSI) and dimensions?

A:Yes, we support full customization of CPSI (10–600), size, wall thickness, and geometry based on your technical drawings or usage requirements.

Q:What materials are your honeycomb ceramics made of?

A:We offer honeycomb ceramics made from Cordierite, Mullite, and Alumina. The material selection depends on your application temperature, chemical environment, and required thermal properties.

Q:Can I customize the cell density (CPSI) and dimensions?

A:Yes, we support full customization of CPSI (10–600), size, wall thickness, and geometry based on your technical drawings or usage requirements.

Q:What is the maximum operating temperature of your honeycomb ceramics?

A:Our honeycomb ceramics can operate safely up to 1350°C, depending on the material used.

Q:Do you offer catalytic coating services?

A:Yes. We provide precious metal catalyst coatings (Pt, Pd, Rh) for automotive applications and SCR coatings (V₂O₅–WO₃–TiO₂) for NOx reduction systems.

Q:Which industries typically use your honeycomb ceramics?

A:Our products are widely used in:

•Regenerative thermal oxidizers (RTOs)

•Automotive catalytic converters (TWC)

•Industrial SCR systems

•High-temperature regenerative burners

•Waste gas treatment in metallurgy and chemical industries

Q: What is your minimum order quantity (MOQ)?

A: MOQ varies by size and customization level. For standard sizes, the MOQ is 100 pieces. Contact us for custom orders.

Q:How do you package the honeycomb ceramics for export?

A:We use shock-proof packaging: foam-filled cartons or wooden crates with pallet support to prevent damage during transportation.

Q:Can you provide samples for testing?

A:Yes, free samples are available for qualified buyers. Shipping costs may apply.

Q:What materials are your honeycomb ceramics made of?

A:We offer honeycomb ceramics made from Cordierite, Mullite, and Alumina. The material selection depends on your application temperature, chemical environment, and required thermal properties.

Q:Can I customize the cell density (CPSI) and dimensions?

A:Yes, we support full customization of CPSI (10–600), size, wall thickness, and geometry based on your technical drawings or usage requirements.

Q:What is the maximum operating temperature of your honeycomb ceramics?

A:Our honeycomb ceramics can operate safely up to 1350°C, depending on the material used.

Q:Do you offer catalytic coating services?

A:Yes. We provide precious metal catalyst coatings (Pt, Pd, Rh) for automotive applications and SCR coatings (V₂O₅–WO₃–TiO₂) for NOx reduction systems.

Q:Which industries typically use your honeycomb ceramics?

A:Our products are widely used in:

•Regenerative thermal oxidizers (RTOs)

•Automotive catalytic converters (TWC)

•Industrial SCR systems

•High-temperature regenerative burners

•Waste gas treatment in metallurgy and chemical industries

Q: What is your minimum order quantity (MOQ)?

A: MOQ varies by size and customization level. For standard sizes, the MOQ is 100 pieces. Contact us for custom orders.

Q:How do you package the honeycomb ceramics for export?

A:We use shock-proof packaging: foam-filled cartons or wooden crates with pallet support to prevent damage during transportation.

Q:Can you provide samples for testing?

A:Yes, free samples are available for qualified buyers. Shipping costs may apply.

Q:What materials are your honeycomb ceramics made of?

A:We offer honeycomb ceramics made from Cordierite, Mullite, and Alumina. The material selection depends on your application temperature, chemical environment, and required thermal properties.

Q:Can I customize the cell density (CPSI) and dimensions?

A:Yes, we support full customization of CPSI (10–600), size, wall thickness, and geometry based on your technical drawings or usage requirements.

Q:What is the maximum operating temperature of your honeycomb ceramics?

A:Our honeycomb ceramics can operate safely up to 1350°C, depending on the material used.

Q:Do you offer catalytic coating services?

A:Yes. We provide precious metal catalyst coatings (Pt, Pd, Rh) for automotive applications and SCR coatings (V₂O₅–WO₃–TiO₂) for NOx reduction systems.

Q:Which industries typically use your honeycomb ceramics?

A:Our products are widely used in:

•Regenerative thermal oxidizers (RTOs)

•Automotive catalytic converters (TWC)

•Industrial SCR systems

•High-temperature regenerative burners

•Waste gas treatment in metallurgy and chemical industries

Q: What is your minimum order quantity (MOQ)?

A: MOQ varies by size and customization level. For standard sizes, the MOQ is 100 pieces. Contact us for custom orders.

Q:How do you package the honeycomb ceramics for export?

A:We use shock-proof packaging: foam-filled cartons or wooden crates with pallet support to prevent damage during transportation.

Q:Can you provide samples for testing?

A:Yes, free samples are available for qualified buyers. Shipping costs may apply.

Q:What materials are your honeycomb ceramics made of?

A:We offer honeycomb ceramics made from Cordierite, Mullite, and Alumina. The material selection depends on your application temperature, chemical environment, and required thermal properties.

Q:Can I customize the cell density (CPSI) and dimensions?

A:Yes, we support full customization of CPSI (10–600), size, wall thickness, and geometry based on your technical drawings or usage requirements.

Q:What is the maximum operating temperature of your honeycomb ceramics?

A:Our honeycomb ceramics can operate safely up to 1350°C, depending on the material used.

Q:Do you offer catalytic coating services?

A:Yes. We provide precious metal catalyst coatings (Pt, Pd, Rh) for automotive applications and SCR coatings (V₂O₅–WO₃–TiO₂) for NOx reduction systems.

Q:Which industries typically use your honeycomb ceramics?

A:Our products are widely used in:

•Regenerative thermal oxidizers (RTOs)

•Automotive catalytic converters (TWC)

•Industrial SCR systems

•High-temperature regenerative burners

•Waste gas treatment in metallurgy and chemical industries

Q: What is your minimum order quantity (MOQ)?

A: MOQ varies by size and customization level. For standard sizes, the MOQ is 100 pieces. Contact us for custom orders.

Q:How do you package the honeycomb ceramics for export?

A:We use shock-proof packaging: foam-filled cartons or wooden crates with pallet support to prevent damage during transportation.

Q:Can you provide samples for testing?

A:Yes, free samples are available for qualified buyers. Shipping costs may apply.

Q:What materials are your honeycomb ceramics made of?

A:We offer honeycomb ceramics made from Cordierite, Mullite, and Alumina. The material selection depends on your application temperature, chemical environment, and required thermal properties.

Q:Can I customize the cell density (CPSI) and dimensions?

A:Yes, we support full customization of CPSI (10–600), size, wall thickness, and geometry based on your technical drawings or usage requirements.

Q:What is the maximum operating temperature of your honeycomb ceramics?

A:Our honeycomb ceramics can operate safely up to 1350°C, depending on the material used.

Q:Do you offer catalytic coating services?

A:Yes. We provide precious metal catalyst coatings (Pt, Pd, Rh) for automotive applications and SCR coatings (V₂O₅–WO₃–TiO₂) for NOx reduction systems.

Q:Which industries typically use your honeycomb ceramics?

A:Our products are widely used in:

•Regenerative thermal oxidizers (RTOs)

•Automotive catalytic converters (TWC)

•Industrial SCR systems

•High-temperature regenerative burners

•Waste gas treatment in metallurgy and chemical industries

Q: What is your minimum order quantity (MOQ)?

A: MOQ varies by size and customization level. For standard sizes, the MOQ is 100 pieces. Contact us for custom orders.

Q:How do you package the honeycomb ceramics for export?

A:We use shock-proof packaging: foam-filled cartons or wooden crates with pallet support to prevent damage during transportation.

Q:Can you provide samples for testing?

A:Yes, free samples are available for qualified buyers. Shipping costs may apply.

Q:What materials are your honeycomb ceramics made of?

A:We offer honeycomb ceramics made from Cordierite, Mullite, and Alumina. The material selection depends on your application temperature, chemical environment, and required thermal properties.

Q:Can I customize the cell density (CPSI) and dimensions?

A:Yes, we support full customization of CPSI (10–600), size, wall thickness, and geometry based on your technical drawings or usage requirements.

Q:What is the maximum operating temperature of your honeycomb ceramics?

A:Our honeycomb ceramics can operate safely up to 1350°C, depending on the material used.

Q:Do you offer catalytic coating services?

A:Yes. We provide precious metal catalyst coatings (Pt, Pd, Rh) for automotive applications and SCR coatings (V₂O₅–WO₃–TiO₂) for NOx reduction systems.

Q:Which industries typically use your honeycomb ceramics?

A:Our products are widely used in:

•Regenerative thermal oxidizers (RTOs)

•Automotive catalytic converters (TWC)

•Industrial SCR systems

•High-temperature regenerative burners

•Waste gas treatment in metallurgy and chemical industries

Q: What is your minimum order quantity (MOQ)?

A: MOQ varies by size and customization level. For standard sizes, the MOQ is 100 pieces. Contact us for custom orders.

Q:How do you package the honeycomb ceramics for export?

A:We use shock-proof packaging: foam-filled cartons or wooden crates with pallet support to prevent damage during transportation.

Q:Can you provide samples for testing?

A:Yes, free samples are available for qualified buyers. Shipping costs may apply.

Q:What materials are your honeycomb ceramics made of?

A:We offer honeycomb ceramics made from Cordierite, Mullite, and Alumina. The material selection depends on your application temperature, chemical environment, and required thermal properties.

Q:Can I customize the cell density (CPSI) and dimensions?

A:Yes, we support full customization of CPSI (10–600), size, wall thickness, and geometry based on your technical drawings or usage requirements.

Q:What is the maximum operating temperature of your honeycomb ceramics?

A:Our honeycomb ceramics can operate safely up to 1350°C, depending on the material used.

Q:Do you offer catalytic coating services?

A:Yes. We provide precious metal catalyst coatings (Pt, Pd, Rh) for automotive applications and SCR coatings (V₂O₅–WO₃–TiO₂) for NOx reduction systems.

Q:Which industries typically use your honeycomb ceramics?

A:Our products are widely used in:

•Regenerative thermal oxidizers (RTOs)

•Automotive catalytic converters (TWC)

•Industrial SCR systems

•High-temperature regenerative burners

•Waste gas treatment in metallurgy and chemical industries

Q: What is your minimum order quantity (MOQ)?

A: MOQ varies by size and customization level. For standard sizes, the MOQ is 100 pieces. Contact us for custom orders.

Q:How do you package the honeycomb ceramics for export?

A:We use shock-proof packaging: foam-filled cartons or wooden crates with pallet support to prevent damage during transportation.

Q:Can you provide samples for testing?

A:Yes, free samples are available for qualified buyers. Shipping costs may apply.

Q:What materials are your honeycomb ceramics made of?

A:We offer honeycomb ceramics made from Cordierite, Mullite, and Alumina. The material selection depends on your application temperature, chemical environment, and required thermal properties.

A:Our honeycomb ceramics can operate safely up to 1350°C, depending on the material used.

A:Yes. We provide precious metal catalyst coatings (Pt, Pd, Rh) for automotive applications and SCR coatings (V₂O₅–WO₃–TiO₂) for NOx reduction systems.

Q:Which industries typically use your honeycomb ceramics?

A:Our products are widely used in:

•Regenerative thermal oxidizers (RTOs)

•Automotive catalytic converters (TWC)

•Industrial SCR systems

•High-temperature regenerative burners

•Waste gas treatment in metallurgy and chemical industries

Q: What is your minimum order quantity (MOQ)?

A: MOQ varies by size and customization level. For standard sizes, the MOQ is 100 pieces. Contact us for custom orders.

Q:How do you package the honeycomb ceramics for export?

A:We use shock-proof packaging: foam-filled cartons or wooden crates with pallet support to prevent damage during transportation.

Q:Can you provide samples for testing?

A:Yes, free samples are available for qualified buyers. Shipping costs may apply.

Zhengzhou Zhongkeda Refractory Materials Co., Ltd

Zhengzhou Zhongkeda Refractory Materials Co., Ltd